Military Warheads as a Source of Nuclear Fuel

- Weapons-grade uranium and plutonium surplus to military requirements in the USA and Russia is being made available for use as civil fuel.

- Weapons-grade uranium is highly enriched, to over 90% U-235 (the fissile isotope). Weapons-grade plutonium has over 93% Pu-239 and can be used, like reactor-grade plutonium, in fuel for electricity production.

- Highly-enriched uranium from weapons stockpiles has been displacing some 8850 tonnes of U3O8 production from mines each year, and met about 13% to 19% of world reactor requirements through to 2013.

For more than five decades, concern has centred on the possibility that uranium intended for commercial nuclear power might be diverted for use in weapons. This gave way to a focus on the role of military uranium as a major source of fuel for commercial nuclear power.

Since 1987 the United States and countries of the former USSR have signed a series of disarmament treaties to reduce the nuclear arsenals by about 80%.

Nuclear materials declared surplus to military requirements by the USA and Russia have been converted into fuel for commercial nuclear reactors. This continues. With the disintegration of the Soviet Union, a unique opportunity arose to deploy military weapons material for making electricity. A 1993 agreement covered essentially the enrichment component of this material, but left unresolved the question of feed from mines, and a 1999 agreement dealt with what happened to the feed material.

The main weapons material is highly enriched uranium (HEU), containing at least 20% uranium-235 (U-235) and usually about 90% U-235. HEU can be blended down with uranium containing low levels of U-235 to produce low-enriched uranium (LEU), less than 5% U-235, fuel for power reactors. It is blended with depleted uranium (mostly U-238), natural uranium (0.7% U-235), or partially-enriched uranium.

Highly-enriched uranium in US and Russian weapons and other military stockpiles amounts to about 1500 tonnes*, equivalent to about seven times annual world mine production.

* according to TradeTech: Russia 720 t +/- 120 t, USA 600 t.

World stockpiles of weapons-grade plutonium are reported to be some 260 tonnes, which if used in mixed oxide fuel in conventional reactors would be equivalent to a little over one year's world uranium production. Military plutonium can blended with uranium oxide to form mixed oxide (MOX) fuel.

After LEU or MOX is burned in power reactors, the spent fuel is not suitable for weapons manufacture.

Megatons to Megawatts, the Russian HEU deal

Commitments by the USA and Russia to convert nuclear weapons into fuel for electricity production was known as the Megatons to Megawatts program.

Surplus weapons-grade HEU resulting from the various disarmament agreements led in 1993 to an agreement between the US and Russian governments. Under this Russia would convert 500 tonnes of HEU from warheads and military stockpiles (equivalent to around 20,000 bombs) to LEU to be bought by the USA for use in civil nuclear reactors.

In 1994, a US$13 billion implementing contract was signed between the US Enrichment Corporation (now USEC Inc) and Russia's Techsnabexport (Tenex) as executive agents for the US and Russian governments. USEC purchased 500 tonnes of weapons-grade HEU over 20 years to 2013, at a rate of up to 30 tonnes/year from 1999. The HEU was progressively blended down to 14,446 t of LEU in Russia, using 1.5% U-235 (re-enriched depleted uranium tails), to restrict levels of U-234 and U-236 in the final product to western specifications.* USEC then sold the LEU to its utility customers as fuel. The LEU enrichment levels specified in the agreement were 3.6%, 4.0%, 4.4% and 4.95%, though it is understood that 4.4% was typical, and possibly that used in the later years of the agreement.

* HEU metal is first removed from a warhead, machined into shavings, oxidized and fluorinated. The resulting highly enriched uranium hexafluoride is then mixed in a gaseous stream with slightly enriched uranium to form LEU suitable for commercial nuclear reactors. The LEU is transferred to shipping cylinders and sent to a collection point in St. Petersburg, Russia. USEC took possession of the material there and shipped it to the USA where it was included in USEC’s inventory for delivery to customers.

It was essentially an enrichment deal totalling about 90 million SWU. About 150,000 t of natural uranium was exchanged for the LEU, of which 112,000 t sold on the market under the terms of the 1999 feed agreement and 38,000 t sent to Russia. This is equivalent to an average of 8850 t/yr of U3O8 from mines over the 20 years. In the latter years it supplied about 13% of world uranium demand.

Overall the blending down of 500 tonnes of Russian HEU resulted in about 14,446 tonnes of LEU over 20 years. This is equivalent to about 150,000 tonnes of natural U (177,000 t U3O8), about 2.5 times annual world demand.

In 1999 a supplementary agreement addressed what should happen to the uranium feed from mines, against which the blended down LEU was supplied to customers. See section below on the 1999 Agreement.

The last of the 500 tonnes of HEU was downblended in August 2013 by Russia’s ElectroChemical Plant (ECP) at Zelenogorsk and shipped in November. Other plants involved in the project were Urals Electrochemical Combine at Novouralsk, Siberian Chemical Combine at Seversk, Angarsk Electrolysis & Chemical Combine, and PA Mayak at Ozersk. The whole deal is equivalent to 20,000 nuclear warheads and 89 million SWU. According to Tenex, total revenue was US$17 billion, including hard currency gains and the cost of natural uranium component.

Russia has other military HEU which it may blend down for its own use, using simply depleted uranium (giving a satisfactory grade of LEU for use in Russian reactors).

US HEU disposition

For its part, the US government initially declared just over 174 tonnes of HEU (of various enrichments) to be surplus from military stockpiles. Of this, USEC took delivery of 14.2 tonnes in the form of uranium hexafluoride (UF6) containing around 75% U-235, and 50 tonnes as uranium oxide or metal containing around 40% U-235. Downblending of the UF6 was completed in 1998, to produce 387 tonnes of LEU. Some 13.5 tonnes of the HEU oxide or metal had been processed by September 2001 to produce 140.3 tonnes of LEU. In 2004 the Nuclear Regulatory Commission issued a licence for downblending 33 tonnes HEU by Nuclear Fuel Services in Tennessee and in 2005 the first delivery was made to a TVA power plant.

DOE's National Nuclear Security Administration (NNSA)* in 2005 announced plans to remove a further 200 tonnes of HEU from military stockpiles. Of this, 160 tonnes was retained for naval propulsion, thus postponing the need for building a new uranium high-enrichment facility for at least 50 years. An additional 20 tonnes was reserved for space missions and for research reactors. The final 20 tonnes was to be downblended to LEU for research reactors, power generation and for 17 tonnes, the new reliable fuel supply initiative (see below).

* Established by Congress in 2000, NNSA is a separately organized agency within the U.S. Department of Energy responsible for enhancing national security through the military application of nuclear science. NNSA maintains and enhances the safety, security, reliability and performance of the U.S. nuclear weapons stockpile without nuclear testing; works to reduce global danger from weapons of mass destruction; provides the U.S. Navy with safe and effective nuclear propulsion; and responds to nuclear and radiological emergencies in the United States and abroad.

Also in 2005, NNSA said that it was committing about 40 tonnes of off-specification HEU (with elevated levels of U-236) to the Blended Low-Enriched Uranium (BLEU) program. This material would be used by TVA. In 2008 NNSA was negotiating with TVA to release a further 21 tonnes of HEU under the program, which would yield about 250 tonnes of LEU, some of which might be sold to other utilities.

In mid-2007 the NNSA awarded contracts to Nuclear Fuel Services and Wesdyne International to downblend 17.4 tonnes of HEU from dismantled warheads to be part of a new international fuel reserve. NFS downblended the material in Tennessee to yield some 290 tonnes of LEU (4.95% U-235) by early 2012. Wesdyne, the prime contractor, is then storing 230 tonnes of the LEU at the Westinghouse fuel fabrication plant in South Carolina to be available for the American Assured Fuel Supply (AFS) program. It will take about 60 tonnes as payment in kind, to be sold on the market over a three to four year period. This first batch of LEU will be available for use in civilian reactors by nations in good standing with the International Atomic Energy Agency that have good nonproliferation credentials and are not pursuing uranium enrichment and reprocessing technologies. It will also now be available to domestic utilities. The fuel – worth some $500 million – will be sold at the current market price.

In June 2009 NNSA awarded a further contract ($209 million) to NFS and Wesdyne for 12.1 tonnes of HEU which will yield some 220 tonnes of LEU by 2012. This second batch of LEU is to provide fuel supply assurance for utilities which participate in DOE's mixed-oxide fuel program utilising surplus plutonium from US weapons. (The AFS scheme is consistent with international concerns to limit the spread of enrichment technology to countries without well-established nuclear fuel cycles. Russia has agreed to join the initiative.)

In the short term most US military HEU is likely to be blended down to 20% U-235, then stored. In this form it is not useable for weapons.

How the Market Works

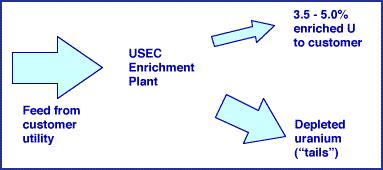

Normally, a utility buys natural uranium from a mining company as "yellowcake" (U3O8) and has it converted to UF6. It then supplies this feed to USEC, paying them for the enrichment component. USEC runs its energy-intensive enrichment plant to separate an appropriate amount of enriched uranium (eg at 3.5 - 5.0% U-235, leaving a lot of depleted uranium). USEC then returns the enriched uranium to the utility for its reactor.

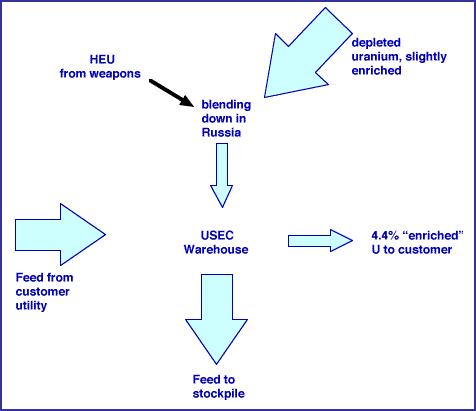

A different, and somewhat complicated, system is used for the Russian material. The utility supplies the feed component of natural uranium as before and pays USEC for the enrichment component. But instead of running their plant, USEC pays the Russians for some blended-down weapons uranium and passes this on to the customer utility as "enriched" uranium fuel. The customers receive the blended-down Russian material, paid for as if it were their own uranium which had been enriched.

USEC pays Russia for the enrichment services component (basically energy) of the low-enriched product it receives. This amounts to about 5.5 million SWU per year. Russia takes ownership of the corresponding amount of natural uranium "feed" provided to USEC by its utility customers for toll enrichment services. Under the 1999 agreement (below) at least 72% of the feed is sold to Cameco, Areva and Nukem in the proportion 45/45/10, and the remainder is sent to Russia for domestic use there. In 2009 Rosatom said that its portion of the natural uranium feed to date – worth US$ 2.7 billion – had been received in Russia.

1999 Market Agreement re natural uranium feed to USEC

After years of stalled negotiations on this matter, a major agreement was approved early in 1999 by the US and Russian governments. It involved 163,000 tonnes of natural U3O8 feed to be supplied over the remaining 15 years of the US-Russian HEU agreement.

Cameco, Cogema (now Areva), and Nukem signed the commercial agreement with Tenex of Russia, giving them "exclusive options to purchase" 118,000 tonnes of this (nominally 70%), leaving the remainder "available to Tenex". One important stipulation was that stockpiles, each of some 26,000 tonnes U3O8, would be held by both Russian and US governments for ten years, to 2009. The US stockpile already existed, Russia's was built up over the next few years from all feed not purchased by Tenex or an associate, and Russia was free to sell only what exceeded this.

The new agreement did not change the overall supply and demand situation, but it removed some major uncertainties over how the material would be released to the market.

The 1993 agreement significantly depressed uranium exploration activities and the uranium price, which took until about 2003 to recover.

Plutonium and MOX

Disarmament will also give rise to some 150-200 tonnes of weapons-grade plutonium (Pu). Weapons-grade plutonium has over 93% of the fissile isotope, Pu-239, and can be used, like reactor-grade Pu, in fuel for electricity production. Options considered for it included:

- Immobilisation with high-level waste - treating plutonium as waste,

- Fabrication with uranium oxide as a MOX fuel for burning in existing reactors,

- Fabrication with thorium as a fuel for existing Russian reactors,

- Fuelling fast-neutron reactors.

In 1994 the USA announced that about half of its military plutonium stockpile was surplus to military requirements. This included non-pit material, and about 20 tonnes of it was of such quality that it might not be possible to utilize it for MOX. In 2012 the US DOE plutonium inventory was announced as being 95.4 tonnes as of 2009, after some transuranic wastes containing 4.8 t of plutonium had been disposed of at the Waste Isolation Pilot Plant (WIPP) in New Mexico. The 95.4 t was composed of 81.3 t weapons grade, 12.7 t fuel grade, and 1.4 t reactor grade plutonium. Since 1944, 103.4 tonnes has been produced, and a further 8.0 t had come from industry, foreign countries and research reactors. Some 3.4 tonnes had been used in tests, 7.8 t discarded as waste and 2.8 t otherwise removed. Russia’s inventory of weapons-grade plutonium is unknown, but is assumed to be of the same order as USA’s.

In June 2000, the USA and Russia agreed to dispose of at least 34 tonnes each of weapons-grade plutonium by 2014. The USA undertook to pursue a dual track program (immobilisation and MOX), self-funded, while the G-7 nations were to provide some US$ 2.5 billion to set up Russia's program. The latter was initially MOX-oriented for VVER reactors, the high cost being because this was not part of Russia's fuel cycle policy. The USA agreed to allow the Russian plutonium to be used in BN-600 and BN-800 fast neutron reactors, and the timeline stretched to 2018. However, the G7 funding was not available on this basis and Russia is funding most of the program, with the USA contributing $400 million. The 68 tonnes of weapons-grade plutonium in both countries is equivalent to about 12,000 tonnes of natural uranium.

In 2011 an amending protocol to the 2000 agreement came into force, confirming the Russian use of fast reactors and specifying a weapons plutonium disposition rate of 1.3 t/yr in each country from 2018. However, after the Russian MOX plant had been built and the US project stalled, Russia unilaterally cancelled the agreement in October 2016. A bill was introduced to Russia’s parliament, with an explanatory note saying that there were both political and technical reasons to cancel the deal, even though it could be renewed under certain conditions related to relaxing US sanctions. The presidential decree said the main reason for cancellation is "the emergence of a threat to strategic stability as a result of US hostile actions against Russia."

Weapons-grade plutonium entering the civil fuel cycle needs to be kept under very tight security, and there are some technical measures needed to achieve this. MOX fuel made from it should degrade it so that Pu-239 cannot be extracted. As it became clear that this could be achieved, the USA dropped its immobilisation plans for most military plutonium,* and this is reflected in the April 2010 agreement with Russia.

USA projects

After environmental and safety reviews, the US Nuclear Regulatory Commission authorized construction of a MOX fuel fabrication plant (MFFF) at the DOE Savannah River site in South Carolina by Duke, Cogema, Stone & Webster. Construction started in August 2007, by Shaw Areva MOX Services. It would make about 1700 civil MOX fuel assemblies from depleted uranium and at least 34 tonnes of weapons-grade plutonium, unlike other MOX plants which use fresh reactor-grade plutonium having around one third non-fissile plutonium isotopes. US reactors using MOX fuel will need to licensed for it. The MFFF is designed to turn 3.5 t/yr of weapons-grade plutonium into about 150 MOX fuel assemblies, both PWR and BWR. The project includes a facility for plutonium pits dismantlement and metallic plutonium conversion to oxide which is complex and has delayed progress.

Shaw Areva MOX Services is under contract to the National Nuclear Security Administration (NNSA), which will own the plant, originally expected to be in operation from 2016, then 2019. The high cost of the plant – $3.5 billion plus $1.3 billion contingency and $183 million per year to operate - is justified on non-proliferation grounds. Annual cost would be offset by revenue.* However, early in 2014 the project was excluded from the DOE budget request for NNSA due to cost escalation, so faced being shut down while 60% complete. This would leave the USA in default on the 2000 bilateral agreement, while Russia has fulfilled its side.

In June 2005 the first four fuel assemblies with mixed oxide fuel made from US military plutonium (plus depleted uranium) started generating electricity in Duke Power's Catawba-1 nuclear power plant in South Carolina, on a trial basis. They incorporated 140 kg of weapons-grade plutonium. The plutonium was made into 2 tonnes of pellets at the Cadrache plant and then fabricated into fuel assemblies at the Melox plant in France. This trial was concluded satisfactorily.

DOE was moving all its surplus non-pit weapons plutonium – reported to be 12.8 tonnes – to Savannah River by 2010. Once the material is consolidated there, the Department's plans for disposing of it involve the use of three Savannah River site facilities: the MOX Fuel Fabrication Facility (MFFF, under construction) for 7.8 tonnes, the existing H-Canyon processing plant followed by a proposed new small-scale plutonium vitrification plant for the balance of 5.0 tonnes. The H-Canyon facility* is the last such US plant able to treat used HEU fuel and similar materials still operational.

* H-Canyon dates from 1955 and originally recovered uranium, neptunium and plutonium from used military and research reactor HEU fuel. Since 1998 it has recovered HEU from degraded materials and spent fuel, to recycle it as LEU. This program will continue to 2019.

Following DOE's September 2007 addition of 9 tonnes of plutonium from dismantled weapons to the MOX program, making 43.4 tonnes surplus to defence needs and designated for MOX, NNSA decided that the Savannah River plant might also produce starter fuel for advanced fast reactors, part of the advanced fuel cycle initiative (AFCI) program.

Meanwhile the US has developed a "spent fuel standard". This specifies that plutonium should never be more accessible than if it were incorporated in spent fuel and thus protected from interference by strong gamma radiation. The plutonium immobilisation plant, if and when it is eventually built, would thus incorporate the plutonium in a version of Synroc ( artificial rock), and encase small discs of this in canisters of vitrified high-level radioactive waste. Alternatively, plutonium would be mixed with fission products and vitrified at the small plant proposed for Savannah River.

Europe's well-developed MOX capacity suggests that weapons plutonium could be disposed of relatively quickly. Input weapons-grade plutonium might need to be mixed with reactor grade material or blended with Pu-238, but using such MOX as 30% of the fuel in one third of the world's reactor capacity would remove about 15 tonnes of warhead plutonium per year. This would amount to burning 3000 warheads per year to produce 110 billion kWh of electricity.

About 40 reactors in Europe are licensed to use MOX fuel, and 30 French reactors are licensed to use it as 30% of their fuel.

Russian projects

Russia is using its plutonium to fuel fast neutron reactors such as its BN-600 and BN-800, and later BREST at Beloyarsk. The USA earlier insisted that it duplicate US plans to make it into MOX fuel for late-model conventional reactors, and for this Russia insisted that the USA pay all costs. But after announcement of the Global Nuclear Energy Partnership in 2006 with its proposals for use of fast reactors, US objection to Russian plans disappeared. The 34 tonnes of plutonium initially available for MOX would have been enough for 1350 fuel assemblies for light-water reactors, but instead is going into MOX fuel for BN-600 and BN-800 fast reactors – the former with one-third MOX core and the latter with full MOX core, and accounting for most of the usage. The USA has agreed to contribute US$ 400 million towards the cost of this – much less than for the MOX option in VVER reactors. The BN-600 will be run without a breeding blanket and the BN-800 at conversion ratio of less than 1.

A small pelletized MOX fuel fabrication plant has operated at the Mayak Production Association facility at Ozersk since 1993, for BN-600 fuel (40 fuel assemblies per year), and it supplied some initial pelletized MOX fuel for BN-800 start-up.

The 60 t/yr commercial MOX Fuel Fabrication Facility (MFFF) commenced operation at Zheleznogorsk in 2015, operated by the Mining & Chemical Combine (MCC). It represents the first industrial-scale use of plutonium in the Russian civil fuel cycle. It makes pelletized MOX fuel assemblies for the BN-800 and future BN-1200 fast reactors. The MOX can have up to 30% plutonium. The Research Institute of Atomic Reactors (RIAR or NIIAR) at Dimitrovgrad, has a small MOX fuel fabrication plant producing vibropacked fuel which is more readily recycled.

In collaboration with TVEL, the Siberian Chemical Combine (SCC) at Seversk is making test batches of dense mixed nitride uranium-plutonium (MNUP) fuel for fast reactors, essentially prototype fuel for BREST fast reactors which are being developed. Burning SCC’s test batch MNUP fuel in the BN-600 fast reactor commenced in 2015. The BN-800 reactor has a uranium blanket but will operate as a net plutonium consumer for the life of the disposition project. Jointly the two BN reactors are expected to burn 1.5 tonnes of this weapons plutonium per year.

The USA and Russia earlier intended to continue cooperative development of a gas-cooled high-temperature reactor (GT-MHR) in Russia which was to "create additional possibilities for speeding up plutonium disposition" from about 2015. This plan has lapsed.

The 2000 US-Russian agreement precludes the reprocessing of MOX fuel using military plutonium if the plutonium is separated out, so such reprocessing will be either to give plutonium plus uranium or plus actinides. Russia is said to have 40 tonnes of separated reactor-grade plutonium already from reprocessed fuel.

UK plans

In 1998 the UK held an estimated 7.6 tonnes of military plutonium, of which 3.5 tonnes was weapons-grade. A total of 4.4 tonnes was subsequently declared surplus to military needs. (The UK also holds about 100 tonnes of reactor-grade plutonium for which uses are being evaluated.)

Thorium-plutonium fuel project

Since the early 1990s Russia has had a program to develop a thorium-uranium fuel, which then moved to have a particular emphasis on utilisation of weapons-grade plutonium in a thorium-plutonium fuel. The program was based at Moscow's Kurchatov Institute and involved the US company Lightbridge Corporation (formerly Thorium Power) and US government funding to design fuel for Russian VVER-1000 reactors.

Whereas normal fuel uses enriched uranium oxide throughout the fuel assembly, the new design has a demountable centre portion and blanket arrangement, with plutonium-zirconium metal fuel rods in the centre and uranium-thorium oxide pellets in conventional fuel rods around it*. The Th-232 in the blanket captures neutrons to become U-233, which is fissile – as is the core Pu-239. Blanket material remains in the reactor for nine years but the centre portion is burned for only three years (as in a normal VVER). Design of the seed fuel rods in the centre portion draws on extensive experience of Russian navy reactors.

* More precisely: A normal VVER-1000 fuel assembly has 331 rods each 9 mm diameter forming a hexagonal assembly 235 mm wide. Here, the centre portion of each assembly is 155 mm across and holds the seed material consisting of metallic Pu-Zr alloy (Pu is about 10% of alloy, and isotopically over 90% Pu-239) as 108 twisted tricorn-section rods 12.75 mm across with Zr-1%Nb cladding. The sub-critical blanket consists of U-Th oxide fuel pellets (1:9 U:Th, the U enriched up to almost 20%) in 228 Zr-1%Nb cladding tubes 8.4 mm diameter - four layers around the centre portion. The blanket material achieves 100 GWd/t burn-up. Together as one fuel assembly the seed and blanket have the same geometry as a normal VVER-1000 fuel assembly.

The thorium-plutonium fuel claims four advantages over MOX: proliferation resistance, compatibility with existing reactors – which will need minimal modification to be able to burn it, and the fuel can be made in existing plants in Russia. In addition, a lot more plutonium can be put into a single fuel assembly than with MOX, so that three times as much can be disposed of as when using MOX. The spent fuel amounts to about half the volume of MOX and is even less likely to allow recovery of weapons-useable material than spent MOX fuel, since less fissile plutonium remains in it. With an estimated 150 tonnes of weapons Pu in Russia, the thorium-plutonium project would not necessarily cut across existing plans to make MOX and mixed nitride fuel. However, the program appears to have lapsed.

See also information papers: Plutonium, Mixed Oxide Fuel, Fuel Fabrication and Synroc.

Notes & references

Ivanov, 2000, paper in Proceedings of 25th UI Symposium.

NATO ASI series, 1994, Managing the Plutonium Surplus: Applications and Technical Options.

Underhill, D H, 1998, paper to U'98 Conference, Adelaide.

NNSA, US-Russia Partnership Reaches Key Milestone in Converting Russian Nuclear Weapons into US Nuclear Fuel, 24 June 2013.

Thorium Power 2003, Weapons-grade Plutonium Burning Fuel for Russian VVER-1000 Nuclear Power Plants.

Morozov et al, Thorium fuel as a superior approach to disposing of excess weapons-grade plutonium in Russian VVER-1000 reactors, Nuclear Future, Vol 1 No. 1 (2005)