Nuclear Power in India

- India has a largely indigenous nuclear power programme.

- The Indian government is committed to growing its nuclear power capacity as part of its massive infrastructure development programme.

- The government has set ambitious targets to grow nuclear capacity.

- Because India is outside the Nuclear Non-Proliferation Treaty due to its weapons programme, it was for 34 years largely excluded from trade in nuclear plant and materials, which hampered its development of civil nuclear energy until 2009.

- Since 2010, a fundamental incompatibility between India’s civil liability law and international conventions limits foreign technology provision.

- Due to earlier trade bans and lack of indigenous uranium, India has uniquely been developing a nuclear fuel cycle to exploit its reserves of thorium.

Reactors

Construction

Shutdown

Operable nuclear power capacity

Electricity sector

Total generation (in 2023): 1958 TWh

Generation mix: coal 1471 TWh (75%); hydro 149 TWh (8%); solar 113 TWh (6%); wind 82.1 TWh (4%); natural gas 52.6 TWh (3%); nuclear 48.2 TWh (2%); biofuels & waste 37.3 TWh (2%); oil 4.2 TWh.

Import/export balance: 0.2 TWh net export

Per capita consumption: c. 1400 kWh

Source: Ember Electricity Data Explorer and Our World in Data.

Energy policy

India has a population of over 1.3 billion and a fast-growing economy. Energy demand is expected to grow more in India than any other country over the next decade. India’s priorities are economic growth and to alleviate poverty. As such, coal is to remain the largest source of energy supply until at least the middle of the century. At COP26 India pledged to cut its emissions to net zero by 2070 – the first time it made such a commitment.

Nuclear energy plays an important role in the country’s long-term energy strategy. The country has developed an indigenous nuclear power programme, based on a fuel cycle which aims to utilize the country’s vast thorium reserves.

In March 2018, the government stated that nuclear capacity would be about 22.5 GWe by the year 2031c, well below earlier targets (see below). This revised target was reaffirmed by Minister of State Jitendra Singh in December 2022d, and by the Department of Atomic Energy in February 2025.

In December 2023 the government launched Viksit Bharat, its strategy to make India a developed nation by 2047. In July 2024 the country’s 2024-25 budget specified setting up Bharat Small Reactors*. In February 2025 Minister of Finance Nirmala Sitharaman announced the Nuclear Energy Mission for Viksit Bharat, and promised federal funds to develop at least five Indian-designed SMRs to be operational by 2033, as well as amendments to Indian legislation to encourage private sector participation, in the budget for 2025-2026. In the same budget she said that the “development of at least 100 GW of nuclear energy by 2047 is essential for our energy transition efforts.”

* Bharat Small Reactors, first announced in August 2023 by Minister of State Jitendra Singh are expected to be closely based on the existing 220 MWe PHWR technology India has built since the 1980s.

Also in February 2025 India and France signed a letter of intent to partner on advanced modular and small modular reactors. In the same month India and the USA agreed to fully realize the US-India 123 Civil Nuclear Agreement by moving forward with plans to build US-designed reactors in India.

Nuclear power industry

Reactors under construction in India

Nuclear capacity targets

The target since about 2004 was for nuclear power to provide 20 GWe by 2020, but in 2007 the prime minister referred to this as "modest" and capable of being "doubled with the opening up of international cooperation." In June 2009 NPCIL said it aimed for 60 GWe nuclear by 2032, including 40 GWe of PWR capacity and 7 GWe of new PHWR capacity, all fuelled by imported uranium. This 2032 target was reiterated late in 2010 and increased to 63 GWe in 2011. But in December 2011 parliament was told that more realistic targets were 14,600 MWe by 2020-21 and 27,500 MWe by 2032.*

* “The XII Plan [2012-17] proposals ..... envisage start of work on eight indigenous 700 MW pressurized heavy water reactors (PHWRs), two 500 MW fast breeder reactors (FBRs), one 300 MW advanced heavy water reactor (AHWR) and eight light water reactors of 1000 MW or higher capacity with foreign technical cooperation. These nuclear power reactors are expected to be completed progressively in the XIII and XIV Plans.” The 16 PHWRS and LWRs were expected to cost $40 billion. The eight 700 MWe PHWRs were to be built at Kaiga in Karnataka, Gorakhpur in Haryana’s Fatehabad District, Banswara in Rajasthan, and Chutka in Madhya Pradesh.

In July 2014 the new prime minister urged the DAE to triple the nuclear capacity to 17 GWe by 2024. He praised “India's self-reliance in the nuclear fuel cycle and the commercial success of the indigenous reactors.” He also emphasized the importance of maintaining the commercial viability and competitiveness of nuclear energy compared with other clean energy sources. In March 2017 parliament was told that the 14.6 GWe target of nuclear capacity by 2024 was maintained, relative to 6.7 GWe (gross) grid-connected then.

In May 2017 the cabinet approved ten 700 MWe PHWRs as a “fully homegrown initiative” with likely manufacturing orders to Indian industry of about INR 700 billion ($11 billion). These would be at four sites identified in 2015, but without a timeline being specified. The prime minister said it would help transform the domestic nuclear industry, which appeared to suggest lower expectations of establishing new nuclear plants with Western technology from Areva, GE Hitachi, and Westinghouse. No mention was made of the other elements of the 12th five-year plan for 2012-17, i.e. the Western LWRs which were originally intended to accelerate new capacity additions, and also two FBRs and one AHWR. Parliament fully supported the announcement.

In March 2018, the government stated that nuclear capacity would fall well short of its 63 GWe target outlined in the 12th five-year plan for 2012-17, and that total nuclear capacity is likely to be about 22.5 GWe by the year 2031c. These plans have since been reaffirmed.

In February 2025 Minister of Finance Nirmala Sitharaman announced that the “Development of at least 100 GW of nuclear energy by 2047 is essential for our energy transition efforts.”

Other energy information for India: US Energy Information Administration Analysis Brief on India

Industry development

Nuclear power for civil use is well established in India. Since building the two small boiling water reactors at Tarapur in the 1960s, its civil nuclear strategy has been directed towards complete independence in the nuclear fuel cycle, necessary because it is excluded from the 1970 Nuclear Non-Proliferation Treaty (NPT) due to it acquiring nuclear weapons capability after 1970. (Those five countries doing so before 1970 were accorded the status of Nuclear Weapons States under the NPT.)

As a result, India's nuclear power programme has proceeded largely without fuel or technological assistance from other countries (but see later section). The pressurized heavy-water reactor (PHWR) design was adopted in 1964, since it required less natural uranium than the BWRs, needed no enrichment, and could be built with the country’s engineering capacity at that time – pressure tubes rather than a heavy pressure vessel being involved. Its power reactors to the mid-1990s had some of the world's lowest capacity factors, reflecting the technical difficulties of the country's isolation, but rose impressively from 60% in 1995 to 85% in 2001-02. Then in 2008-10 the load factors dropped due to shortage of uranium fuel.

India's nuclear energy self-sufficiency extended from uranium exploration and mining through fuel fabrication, heavy water production, reactor design and construction, to reprocessing and waste management. It has a small fast breeder reactor and is building a much larger one. It is also developing technology to utilize its abundant resources of thorium as a nuclear fuel.

The Atomic Energy Establishment was set up at Trombay, near Mumbai, in 1957 and renamed as Bhabha Atomic Research Centre (BARC) ten years later. Plans for building the first Pressurized Heavy Water Reactor (PHWR) were finalized in 1964, and this prototype – Rajasthan 1, which had Canada's Douglas Point reactor as a reference unit, was built as a collaborative venture between Atomic Energy of Canada Ltd (AECL) and NPCIL. It started up in 1972 and was duplicated Subsequent indigenous PHWR development has been based on these units, though several stages of evolution can be identified: PHWRs with dousing and single containment at Rajasthan 1-2, PHWRs with suppression pool and partial double containment at Madras, and later standardized PHWRs from Narora onwards having double containment, suppression pool, and calandria filled with heavy water, housed in a water-filled calandria vault.

The Indian Atomic Energy Commission (AEC) is the main policy body.

The Nuclear Power Corporation of India Ltd (NPCIL) is responsible for design, construction, commissioning and operation of thermal nuclear power plants. At the start of 2010 it said it had enough cash on hand for 10,000 MWe of new plant. Its funding model is 70% equity and 30% debt financing. However, it is aiming to involve other public sector and private corporations in future nuclear power expansion, notably National Thermal Power Corporation (NTPC) – see subsection below. NTPC is very much larger than NPCIL and sees itself as the main power producer. NTPC is largely government-owned. The 1962 Atomic Energy Act prohibits private control of nuclear power generation, and 2016 amendments allowing public sector joint ventures do not extend to private sector companies, nor allow direct foreign investment in nuclear power, apart from the supply chain.

Specific reactors

In July 2017, eight reactors – 2400 MWe (gross) – of nuclear capacity was fuelled by indigenous uranium and being operated close to their rated capacity. The 14 units (4380 MWe gross) under safeguards were operating on imported uranium at rated capacity.

The two Tarapur 150 MWe boiling water reactors (BWRs) built by GE on a turnkey contract before the advent of the Nuclear Non-Proliferation Treaty were originally 200 MWe. They were downrated due to recurrent problems but have run reasonably well since. They have been using imported enriched uranium (from France and China in 1980-90s and Russia since 2001) and are under International Atomic Energy Agency (IAEA) safeguards. However, late in 2004 Russia deferred to the Nuclear Suppliers' Group and declined to supply further uranium for them. They underwent six months' refurbishment over 2005-06, and in March 2006 Russia agreed to resume fuel supply. In December 2008 a $700 million contract with Rosatom was announced for continued uranium supply to them. In 2015 a further contract was signed with TVEL for pellets which will be incorporated into fuel assemblies at the Nuclear Fuel Complex in Hyderabad. The supply contract was renewed in January 2019.

The two small Canadian (Candu) PHWRs at Rajasthan nuclear power plant started up in 1972 & 1980, and are also under safeguards. Rajasthan 1 was downrated early in its life and has operated very little since 2002 due to ongoing problems. It has been shut down since 2004 as the government considers its future. It is still listed by NPCIL as operable though a parliamentary answer in August 2012 said it “is under extended shutdown for techno-economic assessment on continuation of operations.” In March 2017 the minister said a decision on reopening Rajasthan 1 will be made following the techno-economic assessment. Rajasthan 2 was downrated in 1990. It had major refurbishment 2007-09 and has been running on imported uranium at full capacity.

The 220 MWe PHWRs (202 MWe net) were indigenously designed and constructed by NPCIL, based on a Canadian design. The only accident to an Indian nuclear plant was due to a turbine hall fire in 1993 at Narora, which resulted in a 17-hour total station blackout. There was no core damage or radiological impact and it was rated 3 on the INES scale – a 'serious incident'.

The Madras (MAPS) reactors were refurbished in 2002-03 and 2004-05 and their capacity restored to 220 MWe gross (from 170). Much of the core of each reactor was replaced, and the lifespans extended to 2033/36.

Kakrapar unit 1 was fully refurbished and upgraded in 2009-10, after 16 years of operation, as was Narora 2, with cooling channel (calandria tube) replacement. In March 2016 unit 1 was shut down due to a coolant leak, and repairs ran through to May 2019. Kakrapar 2 was shut down in July 2015 and restarted in September 2018. There was widespread corrosion in both Kakrapar units and coolant channels were replaced.

Following the Fukushima accident in March 2011, four NPCIL taskforces evaluated the situation in India and in an interim report in July made recommendations for safety improvements of the Tarapur BWRs and each PHWR type. The report of a high-level committee appointed by the Atomic Energy Regulatory Board (AERB) was submitted at the end of August 2011, saying that the Tarapur and Madras plants needed some supplementary provisions to cope with major disasters. The two Tarapur BWRs have already been upgraded to ensure continuous cooling of the reactor during prolonged station blackouts and to provide nitrogen injection to containment structures, but further work is recommended. Madras needs enhanced flood defences in case of tsunamis higher than that in 2004. The prototype fast breeder reactor (PFR) under construction next door at Kalpakkam has defences which are already sufficiently high, following some flooding of the site in 2004.

The Tarapur 3&4 reactors of 540 MWe gross (490 MWe net) were developed indigenously from the 220 MWe (gross) model PHWR and were built by NPCIL. The first – Tarapur 4 – was connected to the grid in June 2005 and started commercial operation in September. Tarapur 4's criticality came five years after pouring first concrete and seven months ahead of schedule. Its twin – unit 3 – was about a year behind it and was connected to the grid in June 2006 with commercial operation in August, five months ahead of schedule. Tarapur 3&4 cost about $1200/kW, and are competitive with imported coal.

Future indigenous PHWR reactors will be 700 MWe gross (640 MWe net). The first four are being built at Kakrapar and Rajasthan. They were due online by 2017 after 60 months' construction from first concrete to criticality, but this schedule has slipped by several years. Kakrapar 3 became the first of the four to achieve criticality in July 2020, and the unit was connected to the grid in January 2021. Up to 40% of the fuel they use will be slightly enriched uranium (SEU) – about 1.1% U-235, to achieve higher fuel burn-up – about 21,000 MWd/t instead of one-third of this. Initially this fuel will be imported as SEU.

Kudankulam 1&2: Russia's Atomstroyexport supplied the country's first large nuclear power plant, comprising two VVER-1000 (V-412) reactors, under a Russian-financed US$ 3 billion contract and 1988 Russia-India agreement with 1998 supplement. The cost was reported as Rs 17,270 crore – $2.7 billion – in 2015 but at "over Rs 22,000 crore" ($3.3 billion) by NPCIL in mid-2016, including Rs 9,000 crore escalation due to delays. A subsequent figure was Rs 20,962 crore. A long-term credit facility covered about half the cost of the plant.

The AES-92 units at Kudankulam in Tamil Nadu state have been built by NPCIL and also commissioned and operated by NPCIL under IAEA safeguards. The turbines were made by Silmash in St Petersburg and have evidently given some trouble during commissioning. Unlike other Atomstroyexport projects such as in Iran, there was only a maximum of 80 Russian supervisory staff on the project. This resulted in a more problematical than expected learning curve as Indian engineers adapted to the PWR design from Canadian-type PHWR experience. Construction started in March 2002.

Russia is supplying all the enriched fuel through the life of the plant, though India will reprocess it and keep the plutonium for civil use*. The first unit was due to start supplying power in March 2008 and go into commercial operation late in 2008, but this schedule slipped by six years. In the latter part of 2011 and into 2012 completion and fuel loading was delayed by public protests, but in March 2012 the state government approved the plant's commissioning and said it would deal with any obstruction. Unit 1 started up in mid-July 2013, was connected to the grid in October 2013 and entered commercial operation at the end of December 2014. It had reached full power in mid-year but then required turbine repairs for nearly six months. It generated only 2.8 TWh in its first year, at a cost of under Rs 4.0 per kWh (6 c/kWh). Unit 2 construction was declared complete in July 2015, it was grid-connected in August 2016, and commenced commercial operation at the start of April 2017. Each unit is 917 MWe net.

* The original agreement in 1988 specified return of used fuel to Russia, but a 1998 supplemental agreement allowed India to retain and reprocess it.

While the first core load of fuel was delivered early in 2008 there have been delays in supply of some equipment and documentation. Control system documentation was delivered late, and when reviewed by NPCIL it showed up the need for significant refining and even reworking some aspects. The design basis flood level is 5.44m, and the turbine hall floor is 8.1m above mean sea level. The 2004 tsunami was under 3m.

A small desalination plant is associated with the Kudankulam plant to produce 426 m3/h for it using four-stage multi-vacuum compression (MVC) technology. Another reverse osmosis (RO) plant is in operation to supply local township needs.

Output from Kudankulam 1 is being supplied to India's southern grid and in 2016 divided among five states: Tamil Nadu (56%), Karnataka (22%), Kerala (13%), Andhra Pradesh (5%) and Puducherry (3%).

Kudankulam nuclear power plant, one of India's newest

Kudankulam 3&4 are being built as the first stage of phase 2 at the site and are also AES-92 units being built with Russian technical assistance “within the scope of” the 1988 agreement. Their cost is expected to be Rs 39,747 crore and the project was officially launched in October 2016 (see below under Nuclear Energy Parks). The dome of the reactor building for unit 3 was installed in December 2022. Units 3&4 are expected to be completed in 2025 and 2026 respectively.

Kaiga 3 started up in February 2007, was connected to the grid in April and went into commercial operation in May 2007. Unit 4 started up in November 2010 and was grid-connected in January 2011, but was about 30 months behind the original schedule due to a shortage of uranium. The Kaiga units are not under UN safeguards, so cannot use imported uranium. Kaiga 4 was the last of the 220 MWe PHWRs to enter service.

Rajasthan 5 started up in November 2009, using imported Russian fuel, and in December it was connected to the northern grid. RAPP 6 started up in January 2010 and was grid connected at the end of March. Both are now in commercial operation.

Under plans for the India-specific safeguards to be administered by the IAEA in relation to the civil-military separation plan, eight further reactors were to be safeguarded (beyond Tarapur 1&2, Rajasthan 1&2, and Kudankulam 1&2): Rajasthan 3&4 from 2010, Rajasthan 5&6 from 2008, Kakrapar 1&2 by 2012 and Narora 1&2 by 2014.

In mid-2008 Indian nuclear power plants were running at about half of capacity due to a chronic shortage of fuel. Average load factor for India’s power reactors dipped below 60% over 2006-2010, reaching only 40% in 2008. Some easing after 2008 was due to the new Turamdih mill in Jharkhand state coming online (the mine there was already operating). Political opposition has delayed new mines in Jharkhand, Meghalaya and Telangana.

The 500 MWe Prototype Fast Breeder Reactor (PFBR) started construction in 2004 at Kalpakkam near Madras. It was expected to start up about the end of 2010 and produce power in 2011, but this schedule is delayed significantly. In 2014, 1750 tonnes of sodium coolant was delivered. With construction completed, in June 2015 Bhavini was “awaiting clearance from the AERB for sodium charging, fuel loading, reactor criticality and then stepping up power generation." In March 2020 the government said that commissioning would be in December 2021, but this did not proceed. The approved cost is Rs 5677 crore ($850 million). It is not under IAEA safeguards. The reactor is fuelled with uranium-plutonium oxide. It has a blanket with thorium and uranium to breed fissile U-233 and plutonium respectively.

Initial FBRs will have mixed oxide fuel or carbide fuel but these will be followed by metallic fuelled ones.

In contrast to the situation in the 1990s, most PHWR reactors under construction to 2012 were on schedule (apart from fuel shortages 2007-09), and two – Tarapur 3&4 – were increased in capacity. Future PHWR units will be nominal 700 MWe (630 MWe net).

In 2005 four sites were approved for eight new reactors. Two of the sites – Kakrapar and Rajasthan – would have 700 MWe indigenous PHWR units, Kudankulam would have imported 1000 MWe VVER light water reactors alongside the two being built there by Russia, and the fourth site was greenfield for two 1000 MWe LWR units – Jaitapur (Jaithalpur) in the Ratnagiri district of Maharashtra state, on the west coast. The plan has since expanded to six 1600 MWe EPR units here.

In April 2007 the government gave approval for the first four of eight planned 700 MWe PHWR units: Kakrapar 3&4 and Rajasthan 7&8, to be built by Hindustan Construction using indigenous technology. In mid-2009 construction approval was confirmed, and late in 2009 the finance for them was approved. Site works at Kakrapar were completed by August 2010. First concrete for Kakrapar 3&4 was in November 2010 and March 2011 respectively, after Atomic Energy Regulatory Board (AERB) approval. The AERB approved Rajasthan 7&8 in August 2010, and site works then began. First concrete was in July 2011. Construction was then expected to take 66 months to commercial operation. In September 2009 L&T secured an order for four steam generators for Rajasthan 7&8, having already supplied similar ones for Kakrapar 3&4. In December 2012 L&T was awarded the $135 million contract for balance of turbine island for Rajasthan 7&8.

Their estimated cost was to be Rs 12,320 crore (Rs 123.2 billion, $2.6 billion) each pair. Both these projects were delayed apparently by the reluctance of supply chain companies to provide equipment without NPCIL giving indemnity under the 2010 Civil Liability for Nuclear Damage Act. Delays are also attributed to financial constraints. NPCIL said in July 2016 that delays in the supply of equipment including steam generators from Indian sources plus the nuclear liability issue have put the projects behind schedule, and the Minister of Atomic Energy said that Kakrapar 3&4 were only 75.5% completed and Rajasthan 7&8 were only 61.5% completed then. In March 2020 the government said that Kakrapar 3&4 and Rajasthan 7&8 were expected to be commissioned in October 2020, September 2021, March 2022 and March 2023, respectively. In July 2020, Kakrapur 3 achieved first criticality, and was connected to the grid in January 2021. Kakrapar 4 was connected to the grid in February 2024. Rajasthan 7 was connected to the grid in March 2025. Rajasthan 8 is expected to be connected to the grid in 2026 respectively.

Construction costs of reactors as reported by the AEC are about $1200 per kilowatt for Tarapur 3&4 (540 MWe), $1300/kW for Kaiga 3&4 (220 MWe) and expected $1700/kW for the 700 MWe PHWRs with 60-year life expectancy.

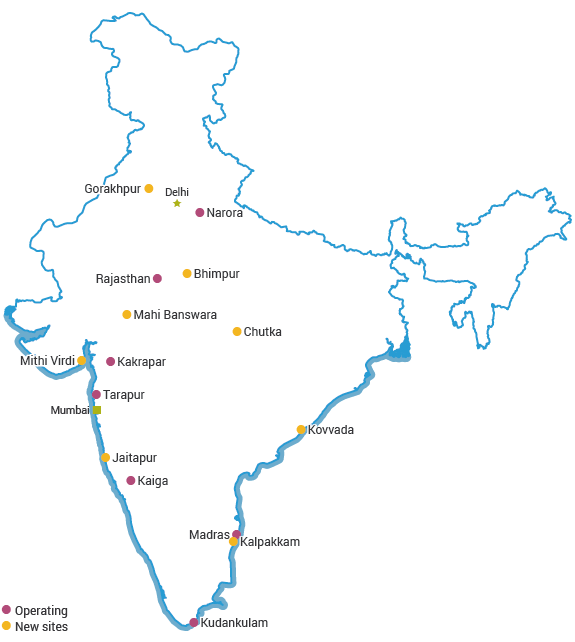

In April 2015 the government gave in principle approval for new nuclear plants at ten sites in nine states. Those for indigenous PHWRs are: Gorakhpur in Haryana's Fatehabad; Chutka and Bhimpur in Madhya Pradesh; Kaiga in Karnataka; and Mahi Banswara in Rajasthan. Those for plants with foreign cooperation are: Kudankulam in Tamil Nadu (VVER); Jaitapur in Maharashtra (EPR); Chhaya Mithi Virdhi in Gujarat (AP1000); Kovvada in Andhra Pradesh (originally ESBWR) and Haripur in West Bengal (VVER), though this location had been in doubt. In addition, two 600 MWe fast breeder reactors are proposed at Kalpakkam. (All these are in line with the 12th five-year plan for 2012-17, with the addition of Bhimpur, which in 2017 was omitted in favour of two extra units at Mahi Banswara.) In mid-2016 the Kovvada site was allocated for AP1000 units instead of Mithi Virdhi, and the ESBWR prospects receded.

New phase of nuclear industry developments

Following the Nuclear Suppliers Group agreement which was achieved in September 2008, the scope for sourcing both reactors and fuel from suppliers in other countries opened up. Civil nuclear cooperation agreements have been signed with the USA, Russia, France, UK, South Korea, Czech Republic and Canada, as well as Australia, Argentina, Kazakhstan, Mongolia and Namibia. A further nuclear cooperation agreement was signed with the UK in November 2015, with “a comprehensive package” of collaboration on energy and climate change matters involving £3.2 billion ($4.9 billion) in programs and initiatives related to energy security and energy access. However, there was no civil nuclear cooperation agreement with Japan, which loomed as a limiting factor for some technology provision involving GE Hitachi and Westinghouse. Eventually a preliminary agreement was signed in December 2015, and after six years of negotiations a full nuclear cooperation agreement was signed in November 2016. It will allow India to import Japanese nuclear technology, and secures Japan’s support for India to join the international Nuclear Suppliers Group (NSG). A civil nuclear cooperation agreement was signed with Japan in 2016 and passed by Japan’s parliament in June 2017.

On the basis of the 2010 cooperation agreement with Canada, in April 2013 a bilateral safeguards agreement was signed between the Department of Atomic Energy (DAE) and the Canadian Nuclear Safety Commission (CNSC), allowing trade in nuclear materials and technology for facilities which are under IAEA safeguards. A similar bilateral safeguards agreement with Australia was signed in 2014 and finalized in November 2015. Both apply essentially to uranium supply.

The initial two Russian PWR types at the Kudankulam site were apart from India's three-stage plan for nuclear power and were simply to increase generating capacity more rapidly. Now there are plans for eight 1000 MWe units at that site, and in January 2007 a memorandum of understanding was signed for Russia to build the next four there, as well as others elsewhere in India. A further such agreement was signed in December 2010, and Rosatom announced that it expected to build no less than 18 reactors in India. Then in December 2014 another high-level nuclear cooperation agreement was signed with a view to Russia building 20 more reactors plus cooperation in building Russian-designed nuclear power plants in third countries, in uranium mining, production of nuclear fuel, and waste management. India was also to confirm a second location for a Russian plant – Haripur in West Bengal being in some doubt. Most of the new units are expected to be the larger 1200 MWe AES-2006 designs. Russia was earlier reported to have offered a 30% discount on the $2 billion price tag for each of the phase 2 Kudankulam reactors. This was based on plans to start serial production of reactors for the Indian nuclear industry, with much of the equipment and components proposed to be manufactured in India, thereby bringing down costs. However, at the end of 2015 the approved cost of Kudankulam units 3&4 was Rs 39,747 crore ($5.96 billion), according to the Minister for Atomic Energy, more than twice the costs of units 1&2, due to liability issues.

Between 2010 and 2020, further nuclear plant construction was expected to take total gross capacity to 21,180 MWe. The planned increment included many of those set out in the Table below ('planned') plus the initial 300 MWe advanced heavy water reactor (AHWR).

Looking beyond the Russian light water reactors, NPCIL had meetings and technical discussions with three major reactor suppliers – Areva, GE Hitachi, and Westinghouse Electric Corporation – for the supply of reactors for these projects and for new units at Kaiga. These resulted in more formal agreements with each reactor supplier early in 2009, as described in the Nuclear Energy Parks subsection below. The benchmark capital cost sanctioned by DAE for imported units was quoted at $1600 per kilowatt. An important aspect of all these agreements is that, as with Kudankulam, India will reprocess the used fuel to recover plutonium for its indigenous three-stage civil program, using a purpose-built and safeguarded integrated nuclear recycle plant. However, all three agreements beyond that with Russia are stalled due to liability concerns.

In late 2008 NPCIL announced that as part of the Eleventh Five Year Plan (2007-12), it would start site work for 12 reactors including the rest of the eight 700 MWe PHWRs, three or four fast breeder reactors and one 300 MWe advanced heavy water reactor (AHWR) in 2009. NPCIL said that "India is now focusing on capacity addition through indigenization" with progressively higher local content for imported designs, up to 80%. Looking further ahead its augmentation plan included construction of 25-30 light water reactors of at least 1000 MWe by 2030. In the event only four 700 MWe PHWR units started construction over 2007-12.

Early in 2012 NPCIL projections had the following additions to the 10.08 GWe anticipated in 2017 as 'possible': 4.2 GWe PHWR, 7.0 GWe PHWR (based on recycled U), 40 GWe LWR, 2.0 GWe FBR. These projections also have not materialized.

In June 2012 NPCIL announced four new sites for twin PHWR units: at Gorakhpur/Kumbariya near Fatehabad district in Haryana, at Banswara in Rajasthan, at Chutka in Mandla district and at Bhimpur also in Madhya Pradesh. Initially these would add 2800 MWe, followed by a further 2800. Site work has started at Gorakhpur with Haryana state government support.

In mid-2015 NPCIL confirmed plans for Kaiga 5&6 as 700 MWe PHWR units, costing about Rs 6000 crore (Rs 60 billion). In September 2019 India's Ministry of Environment, Forest and Climate Change (MoEF) approved NPCIL's plans. The turbine islands and steam generators for Kaiga 5&6 were ordered from BHEL in July and August 2021, and in May 2022 excavation works began.

NPCIL is also planning to build an indigenous 900 MWe PWR, the Indian Pressurised Water Reactor (IPWR), designed by BARC in connection with its work on submarine power plants. A site for the first plant is being sought, a uranium enrichment plant is planned, the reactor pressure vessel forging will be carried out by Larsen & Toubro (L&T) and NPCIL's new joint venture plant at Hazira, and the turbine will come from Bharat Heavy Electricals Limited (BHEL).

Meanwhile, NPCIL is offering both 220 and 540 MWe PHWRs for export, in markets requiring small- to medium-sized reactors.

Power reactors planned (XII plan 2012, April 2015 approval in principle, modified in 2017, 2018 and 2022). Gorakhpur 1-4 and Kaiga 5&6 appear to be the most advanced projects.

| Reactor | State | Type | MWe gross (each) | Project control | Start construction |

| Gorakhpur 1&2 | Haryana (Fatehabad district) | PHWR x 2 | 700 | NPCIL | 2023? |

|---|---|---|---|---|---|

| Gorakhpur 3&4 | Haryana (Fatehabad district) | PHWR x 2 | 700 | NPCIL | Progressively by 2031 |

| Chutka 1&2 | Madhya Pradesh (Mandla) | PHWR x 2 | 700 | NPCIL | |

| Mahi Banswara 1&2 | Rajasthan | PHWR x 2 | 700 | NPCIL | |

| Mahi Banswara 3&4 | Rajasthan | PHWR x 2 | 700 | NPCIL | |

| Kaiga 5&6 | Karnataka | PHWR x 2 | 700 | NPCIL | |

| Subtotal planned | 12 units | 8400 MWe | |||

Power reactors proposed (XII plan 2012)

| Reactor | State | Type | MWe gross (each) | Project control |

| Tarapur? | Maharashtra? | AHWR | 300 | NPCIL |

|---|---|---|---|---|

| "Haripur 1&2" another site |

West Bengal (but likely relocated, maybe to Kavali in Andhra Pradesh) | AES-2006 | 1200 | NPCIL |

| Kalpakkam 2&3 | Tamil Nadu | FBR x 2 | 600 | Bhavini |

| Kudankulam 7&8 | Tamil Nadu | AES 2006 | 1200 | NPCIL |

| "Kudankulam 9-12" | Andhra Pradesh | AES-2006 | 1200 | NPCIL |

| Bhimpur 1-4 | Madhya Pradesh | PHWR | 700 | NPCIL |

| Chutka 3&4 | Madhya Pradesh | PHWR | 700 | BHEL-NPCIL-GE? |

| Rajouli, Nawada 1&2 | Bihar | PHWR | 700 | NPCIL |

| ? | PWR x 2 | 1000 | NPCIL/NTPC | |

| Jaitapur 1&2 | Ratnagiri, Maharashtra | PWR – EPR | 1700 | NPCIL |

| Jaitapur 3&4 | Ratnagiri, Maharashtra | PWR – EPR | 1700 | NPCIL |

| ? | ? | FBR x 4 | 500 | Bhavini |

| Jaitapur 5&6 | Ratnagiri, Maharashtra | PWR – EPR | 1700 | NPCIL |

| Markandi (Pati Sonapur) | Orissa | PWR 6000 MWe | NPCIL | |

| Kovvada 1&2 | Srikakulam, Andhra Pradesh | AP1000 | 1250 | NPCIL |

| Kovvada 3&4 | Srikakulam, Andhra Pradesh | AP1000 | 1250 | NPCIL |

| Earlier: "Kovvada 1-6" | Originally Srikakulam, Andhra Pradesh | Originally ESBWR | 1600 | NPCIL |

| Nizampatnam 1-6 | Guntur, Andhra Pradesh | 6x? | 1200 | NPCIL |

| "Haripur 3-6" another site |

West Bengal, Orissa or Kavali in Andhra Pradesh | AES-2006? | 1200 | NPCIL |

| Pulivendula | Kadapa, Andhra Pradesh | PWR? PHWR? | 1000? 700? | NPCIL 51%, AP Genco 49% |

| Kovvada 5&6 | Srikakulam, Andhra Pradesh | AP1000 | 1250 | NPCIL |

| Chhaya-Mithi Virdi 1-6 | Bhavnagar, Gujarat | AP1000 | 1250 | NPCIL |

List of proposed units includes all known proposals made to date for completeness. Not all units listed as proposed in the above table are likely to be built. The government of India in March 2018 identified 28 units and 32 GWe of capacity as approved "in principle"d. For WNA's reactor table, these figures are listed as "proposed".

Nuclear Energy Parks

In line with past practice such as at the eight-unit Rajasthan nuclear plant, NPCIL intends to set up five further "Nuclear Energy Parks", each with a capacity for up to eight new-generation reactors of 1,000 MWe, six reactors of 1600 MWe or simply 10,000 MWe at a single location. By 2032, 40-45 GWe would be provided from these five. NPCIL was hoping to be able to start work by 2012 on at least four new reactors at all four sites designated for imported plants, but this did not happen. In mid-2015 it was reported that an additional site could be assigned for a Japanese multi-unit plant. However, apart from the Russian projects under inter-governmental agreement, no overseas reactor vendor has been ready to proceed under India’s unique liability arrangements.

Original plans were for widespread deployment of new nuclear capacity, but due to protests in Gujarat, Tamil Nadu, West Bengal and Maharashtra, some of the plans have relocated proposed developments to Andhra Pradesh. That state may now host six Russian reactors moved from Haripur in West Bengal to Kavali in Nellore district, six Westinghouse AP1000 moved from Mithi Virdi in Gujarat to Kovvada in Srikakulam district, as well as the original six GE Hitachi ESBWR units if they are ever approved.

Planned nuclear power plants in India

The five new energy parks include two that are proceeding and one that shows some promise:

Kudankulam (KKNPP) phases 2, 3&4 in Tamil Nadu: three more pairs of Russian AES-92 units with VVER-1000 reactors, making eight, with 9200 MWe were envisaged, but it now appears that after six 1000 MWe reactors, units 7-8 will be the larger AES-2006 design with VVER-1200 reactors. Agreements intended for mid-2010 were delayed on account of supplier liability questions, with India wanting the units to come under its 2010 vendor liability law. In July 2012 coastal regulation zone clearance was obtained for units 3-6 of 1000 MWe each from the Ministry of Environment & Forests, mainly related to seawater cooling. Environmental approval for units 3-6 had been obtained earlier.

Phase 2: In July 2012 Russia agreed to $3.5 billion in export financing for units 3&4, to cover 85% of their cost. A further credit line of $800 million is available to cover fuel supplies. The credit lines carry interest at 4% pa and would be repayable over 14 years and 4 years respectively, from one year after the start of power generation. The Indian government said it expected to take up the credit offers to the value of $3.06 billion, about 53% of the then estimated $5.78 billion total project cost.

In March 2013 cabinet approved construction of units 3&4, and some site preparation began. In April 2014 NPCIL signed a Rs 33,000 crore ($ 5.47 billion) agreement with Rosatom for units 3&4, having apparently resolved the liability question (but see section below). In May a general framework agreement to build the plants was signed, and in December contracts with Rosatom were signed. Rosatom said that the general contractor is Atomstroyexport, and the general designer is Atomenergoproekt. In September 2015 Rosatom contracted Atomenergomash for the complete supply of major components for the two reactors, to be delivered to the plant over 2016-2018. OMZ-Spetsstal completed the pressure vessel forgings for unit 3 in June 2016 and sent them to OMZ Izhorskiye Zavody for fabrication, with internals. AEM-Technology’s Volgodonsk branch (Atommash) will supply the reactor pressure vessel for unit 4 and steam generators for both units, manufacture of which began in November 2016, for shipment in 2018. Some ancillary equipment is from ZiO-Podolsk. Larsen & Toubro is contracted for civil works.

In August 2015 the government said that all issues had been resolved to enable construction of units 3&4 to start. Excavation started in February 2016, the AERB construction permit was issued with construction start a week later in June 2017. A 72-month construction period was expected, under NIAEP-ASE supervision. The project was officially launched in October 2016. The approved project cost is Rs 39,747 crore ($6.25 billion), about double per MW that of established PHWR plants, but using the ruble as currency peg. Generation cost is expected to be about Rs 3.9/kWh (5.8 cents/kWh), competitive with coal. In March 2020 the government said that the units would be commissioned in March 2023 and November 2023.

Phase 3: In October 2016 a general agreement was signed for units 5&6, along with finalizing a credit protocol. A framework agreement was signed in June 2017, including an intergovernmental credit protocol, so that the project entered what Rosatom called the “practical implementation phase”. At the end of July ASE Group and NPCIL signed contracts covering the design and supply of the main plant components for units 5&6. In February 2021 NPCIL contracted Larsen & Toubro for civil works over 64 months. First concrete for unit 5 was in June 2021 and unit 6 in December 2021.

Phase 4: Plans are for units 7&8 to be AES-2006 units with VVER-1200 reactors.

In 2015, due to the nuclear liability law constraints on other foreign reactor vendors, four more Russian units were agreed. However, though broadly discussed as 'Kudankulam', these will be in Andhra Pradesh, possibly at Kavali in Nellore district, and will likely be AES-2006 power plants with VVER-1200 reactors. See Haripur, below.

Gorakhpur Haryana Anu Vidyut Pariyojana (GHAVP) in the Fatehabad district of Haryana is a project with four indigenous 700 MWe PHWR units in two phases, and the AEC has approved the state's proposal for the 2800 MWe plant. Kakrapar 3&4 and Rajasthan 7&8 are the reference design. The inland northern state of Haryana is one of the country's most industrialized and has a demand of 8900 MWe, but currently generates less than 2000 MWe and imports 4000 MWe. The Gorakhpur plant may be paid for by the state government or Haryana Power Generation Corp.

NPCIL is undertaking site infrastructure works near the villages of Kumharia and Gorakhpur, and the official groundbreaking was in January 2014. A final environmental assessment for the project was approved in December 2013, and government approval for Gorakhpur phase 1 was in February 2014. The AERB granted a siting licence in July 2015. Construction was initially due to begin in June 2015, with the first unit online in 2021. The Minister of State for Atomic Energy and Space announced in March 2016 that the first unit would be online in six years, and electricity would be supplied to consumers at the rate of Rs 6.5 ($0.10) per unit. The cost of the first two units was then put at Rs 210 billion ($3.4 billion). In July 2016 NPCIL was seeking bids for domestic supply of equipment, noting that this would be the first plant subject to the 2010 civil liability legislation. NPCIL commenced early site works in 2018, and in November 2020 the AERB approved the pouring of first nuclear safety-related concrete. The turbine islands and steam generators for Gorakhpur 1-4 were ordered from BHEL in July and August 2021.

Three projects are delayed indefinitely, though one may proceed after site reallocation:

Kovvada in Andhra Pradesh's northern coastal Srikakulam district was originally intended to host six GE Hitachi ESBWR units, but is now designated for six Westinghouse AP1000 units.

GE Hitachi said in June 2012 that it was undertaking a preliminary environmental assessment and preparing an early works agreement with NPCIL to set terms for obtaining approval from the government for the project. In February 2014 NPCIL said it hoped to commence construction of the first 1594 MWe reactor early in 2015. However, with no change to the 2010 Civil Liability for Nuclear Damage Act, GEH in September 2015 said it would not proceed with any investment in India until the country’s liability regime was brought into line with the rest of the world. In June 2016 DAE said that it would not support building any reactor design that did not have a reference plant, which ruled out the ESBWR for the time being. This coincided with NPCIL allocating the Kovvada site to Westinghouse for six AP1000 reactors.

In July 2016 the Atomic Energy Minister said that a land survey had been completed, acquisition of 840 ha was proposed. In September 2016 NPCIL submitted an environmental assessment to the environment ministry, requesting clearance to proceed with building the AP1000 plant. A draft social impact study has been completed for the state government. The Indian and US governments have called for continued engagement between Westinghouse and NPCIL towards finalizing the contractual arrangements for the six Kovvada units by June 2017. Westinghouse is proceeding with the project despite it filing for Chapter 11 bankruptcy in the USA, since the project is “structured in a manner that does not include construction risk.” It is proposed to start construction of one unit per year from 2018, with the first operational in 2025.

Jaitapur (JNPP) in Maharashtra's Ratnagiri district: following a February 2009 general agreement with Areva to build six EPR reactors, a €7 billion framework agreement with Areva was signed in December 2010 for the first two, with Alstom turbine-generators, along with 25 years supply of fuel.

Environmental approval has been given for these, with coastal zone clearances. Land acquisition was completed in 2018. The site will host six units, providing 9600 MWe. Areva had hoped to obtain export credit financing and sign a contract by the end of 2012, to put the first two units online in 2020 and 2021. In 2013 negotiations continued and the government said it expected the cost of the first two units to be 120,000 crore ($20 billion). France has agreed to a 25-year loan for the project at 4.8%. In April 2015 Areva signed a pre-engineering agreement contract with NPCIL in preparation for licensing the EPR design. In May 2015 Areva said that construction might begin in two years, with 50% local content in the first units. However timing would be dependent on the resolution of nuclear liability questions. NPCIL has sought an extension of the five-year environmental clearance which expired in November 2015.

In March 2014 Areva and DAE with NPCIL were reported to have agreed on a power price of Rs 6.5/kWh (10.6 US cents/kWh), though Areva had been aiming for Rs 9.18. However, in June 2014 it was reported that there was as yet no agreement and that DAE was adamant that the cost could not be more than Rs 6.5/kWh. Areva was holding out for the higher price.

In January 2016 the prime minister and the French president announced that they "encouraged their industrial companies to conclude techno-commercial negotiations by the end of 2016" on Jaitapur. They called for "due consideration to cost viability of the project, economical financing from the French side, collaboration on transfer of technology and cost-effective localization of manufacturing in India for large and critical components. Their shared aim is to start the implementation of the project in early 2017." France acknowledges the need for India to have a "lifetime guarantee of fuel supply, and renewed its commitment to reliable, uninterrupted and continued access to nuclear fuel supply throughout the entire lifetime of the plants." In July 2016 EdF submitted a fresh proposal to NPCIL and the Ministry of External Affairs for six EPR units, but seeking guarantee of “the same level of protection” in relation to liability that is available at the international level, and citing the Vienna convention on liability. In mid-2017 EdF said it expected to sign a general framework agreement with NPCIL by the end of the year. While EdF is in line to take on the EPC contract, it is also reported as wanting NPCIL to handle most of the construction.

In March 2018, a so-called Industrial Way Forward Agreement was signed by EDF and NPCIL, setting out the industrial framework and planned timetable for the six EPR reactors at Jaitapur. Under its terms, EDF will act as supplier of the EPR technology, and will undertake all engineering studies and component procurement activities for the first two of the six reactors. Responsibility for some purchasing activities and studies for the other four units may be assigned to local companies, reaching potential Indian localization of 60% for the last two of the six reactors. As owner and future operator of the Jaitapur plant, NPCIL will be responsible for obtaining all authorizations and certifications required in India, and for constructing all six reactors and site infrastructures. Upon signing of the agreement, a goal of commencing works at Jaitapur "around the end of 2018" was reiterated. In June 2018, GE and EDF signed a strategic cooperation agreement, described by the two companies as "an important step in implementing the Industrial Way Forward Agreement." GE Power will design the conventional island at Jaitapur and supply its main components. EDF will be responsible for engineering integration across the entire project.

Chhaya-Mithi Virdi in Gujarat's Bhavnagar district was intended to host up to six Westinghouse AP1000 units built in three stages on the coast, and it may yet do so.

NPCIL commenced site works in 2012, and a preliminary environmental assessment for the whole project was completed in January 2013. State and local government and coastal zone clearances were obtained. A preliminary commercial contract between NPCIL and Westinghouse was signed in September 2013 along with an agreement to carry out a two-year preliminary safety analysis for the project. NPCIL said that it “must lay emphasis on strong public acceptance outreach and project planning." In October 2014 the Ministry of Environment & Forests asked NPCIL for further assessment of environmental and land acquisition matters in its environment impact assessment (EIA). NPCIL was then in the process of obtaining site clearance from the Atomic Energy Regulatory Board (AERB). However, the land acquisition process was held up pending passage of a new federal Land Acquisition Act, which was delayed in the upper house. Then in May 2016 NPCIL changed the initial Westinghouse AP1000 site to Kovvada in the northern coastal Srikakulam district of Andhra Pradesh, and in June the government announced that the final contract was to be completed in June 2017. The first stage of two units was originally due online in 2019-20, the others to 2024. Westinghouse still expects to build six AP1000 units at Chhaya-Mithi Virdi however, after those at Kovvada.

In addition to the original five energy parks, there are four proposals and the first two are considered 'planned':

Chutka (CNPP) in inland Madhya Pradesh is also designated for two indigenous 700 MWe PHWR units. NPCIL has initiated pre-project activities here. The EIA report was released in March 2013 and a public hearing at Chutka was in February 2014. The expected cost for two units was then set at Rs 16,550 crore ($2.48 billion). Construction start was planned for 2015, now likely in the early 2020s.

Mahi Banswara in Rajasthan is a new site for 700 MWe PHWRs. Land acquisition, government approval and environmental assessment are in train. Two units were in the 2012 XII Plan, and the government announced in principle approval in August 2016 for the construction of four units. This was confirmed in July 2017.

At Markandi (Pati Sonapur) in Orissa there are plans for up to 6000 MWe of PWR capacity. Major industrial developments are planned in that area and Orissa was the first Indian state to privatize electricity generation and transmission. State demand was expected to reach 20 billion kWh/yr by 2010. However, these plans may have merged with others.

Bhimpur in Madhya Pradesh has in-principle government approval for two 700 MWe PHWRs, according to the DAE annual report 2013-14, but by 2017 plans these had been transferred to Mahi Banswara.

The AEC has also mentioned possible new nuclear power plants in Bihar and Jharkhand.

Haripur in West Bengal: was to host four or six further Russian VVER-1200 units. NPCIL has initiated pre-project activities here, and groundbreaking was planned for 2012. However, strong local opposition led the West Bengal government to reject the proposal in August 2011, and change of site to Orissa state was suggested. In 2015 Andhra Pradesh and Karnataka had expressed interest in hosting further Russian plants. Certainly Rosatom expects to build six further Russian VVER reactors at a new site, not yet identified, and hopes to build up to 14 more after that. Haripur is abandoned. In October 2016 the government and Rosatom said that allocation of a new site was likely soon. Kavali in Andhra Pradesh appears most likely.

In 2014 the Chinese president initiated discussions with his Indian counterpart about building nuclear power plants, raising he possibility that China could compete with France, Russia, Japan and the USA.

Fast neutron reactors

In the longer term, the AEC envisages its fast reactor programme being 30 to 40 times bigger than the PHWR programme, and initially at least, largely in the military sphere until its "synchronized working" with the reprocessing plant is proven on an 18- to 24-month cycle. This would be linked with up to 40,000 MWe of light water reactor capacity, the used fuel feeding ten times that fast breeder capacity, thus "deriving much larger benefit out of the external acquisition in terms of light water reactors and their associated fuel". This 40 GWe of imported LWR capacity multiplied to 400 GWe via FBR would complement 200-250 GWe based on the indigenous three-stage programme of PHWR-FBR-AHWR (see section on Thorium fuel cycle below). Thus AEC is "talking about 500 to 600 GWe nuclear over the next 50 years or so" in India, plus export opportunities.

In 2002 the regulatory authority issued approval to start construction of a 500 MWe prototype fast breeder reactor (PFBR) at Kalpakkam and this has been built by BHAVINI (Bharatiya Nabhikiya Vidyut Nigam Ltd), a government enterprise set up under the DAE to focus on FBRs. It was expected to start up in September 2014, fuelled with MOX (mixed uranium-plutonium oxide, the 30% of reactor-grade Pu being from its existing PHWRs) made at Tarapur by BARC, as hexagonal fuel asemblies. It has a blanket with uranium and thorium to breed fissile plutonium and U-233 respectively, taking the thorium programme to stage two, and setting the scene for eventual full utilisation of the country's abundant thorium to fuel reactors. It is a sodium-cooled pool-type reactor having two primary and two secondary loops, with four steam generators per loop. It is designed for a 40-year operating lifetime at 75% load factor. Two more such 500 MWe fast reactors have been announced for construction at Kalpakkam, but slightly redesigned by the Indira Gandhi Centre to reduce capital cost. Then four more are planned at another site.

Initial FBRs will have mixed oxide fuel or carbide fuel, but these will be followed by metallic fuelled ones to enable shorter doubling time. One of the last of the above six, or possibly the fourth one overall, is to have the flexibility to convert from MOX to metallic fuel (i.e. a dual fuel unit), and it was planned to convert the small FBTR to metallic fuel about 2013 (see R&D section below). With metal fuel, a 500 MWe unit is expected to produce 2 tonnes of reactor-grade plutonium in 8-10 years. The reactor is not under international safeguards.

Following these will be a 1000 MWe fast reactor using metallic fuel. A fuel fabrication plant and a reprocessing plant for metal fuels are planned for Kalpakkam in 2024, known as the Fast Reactor Fuel Cycle Facility (FRFCF). See below.

A December 2010 scientific and technical cooperation agreement between the AEC and Rosatom is focused on "joint development of a new generation of fast reactors".

NPCIL collaboration with other state entities

In February 2016 the government amended the Atomic Energy Act to allow NPCIL to form joint venture companies with other public sector undertakings (PSUs) for involvement in nuclear power generation and possibly other aspects of the fuel cycle. The legislative change does not extend to private sector companies, and nor does it allow direct foreign investment in nuclear power, apart from the supply chain. This is expected to help NPCIL secure funding for new projects.

Three joint venture companies involving major PSUs in the energy area have been incorporated and are able to come into effect under the revised legislation: Anushakti Vidhyut Nigam Ltd (NPCIL and NTPC), NPCIL-Indian Oil Nuclear Energy Corporation Ltd, and NPCIL-Nalco Power Company Ltd. NPCIL itself is reported to have about Rs 12,000 crore ($1.8 billion) of investible surplus; the three other PSUs – NTPC, IOC and Nalco – are able to contribute about Rs 10,000 crore ($1.5 billion) each to new nuclear projects in which they will have 49% equity. Some of this will be in hard currency, which may be why the focus has shifted from indigenous PHWR plants (which can be paid for in local currency) to new plants with imported LWR technology.

NTPC plans

India's largest power company, National Thermal Power Corporation (NTPC) in 2007 had proposed building a 2000 MWe nuclear power plant to be in operation by 2017. It would be the utility's first nuclear plant and also the first conventional nuclear plant not built by the 89.5% government-owned NPCIL. This proposal took the form of a joint venture in 2011 with NPCIL holding 51%, and possibly extending to multiple projects utilising local and imported technology, but pending amendment to the Atomic Energy Act. One of the sites earmarked for a pair of 700 MWe PHWR units in Haryana or Madhya Pradesh was considered prospective for the joint venture. NTPC said it aimed by 2014 to have demonstrated progress in "setting up nuclear power generation capacity", and that the initial "planned nuclear portfolio of 2000 MWe by 2017" could be greater. However in 2012 it indicated a downgrading of its nuclear plans.

NTPC planned to increase its total installed capacity to 70 GWe by 2017 and 128 GWe by 2032, from 47 GWe (74% coal) in 2016. In 2008 it also formed joint ventures in heavy engineering, with BHEL and Bharat Forge. The former is to explore, secure and execute EPC contracts for power plants and other infrastructure projects in India and abroad, as well as manufacturing and supplying equipment for them. With the 2011 JV with NPCIL, this was reported as also selling India's largely indigenous 220 MWe PHWR reactor units abroad, possibly in contra deals involving uranium supply from countries such as Namibia and Mongolia.

Nalco plans

The 87% state-owned National Aluminium Company (Nalco) signed an agreement with NPCIL with the intention of building a 1400 MWe nuclear power plant on the east coast, in Orissa's Ganjam district. A more specific agreement was signed in November 2011 to set up a joint venture with NPCIL – NPCIL Nalco Power Co Ltd – giving it 26% equity in Kakrapar 3&4 (total 1300 MWe net) under construction in Gujarat on the west coast for Rs 1700 crore ($285 million). The total project size is Rs 12,000 crore with the total debt requirement at Rs 7,000 crore. Nalco sought government permission to increase this share to 49%, pending amendment to the Atomic Energy Act. It was also seeking to buy uranium assets in Africa. In May 2016 it was reported to have pulled out of the JV with NPCIL, but at the end of the year the JV continued.

Nalco already has its own 1200 MWe coal-fired power plant in Orissa state at Angul, to serve its refinery and its Angul smelter of 345,000 tpa, being expanded to 460,000 tpa (requiring about 1 GWe of constant supply). It has set up wind farms in Andhra Pradesh (50.4 MWe) and Rajasthan (47.6 MWe).

IOC and ONGC plans

India's national oil company, Indian Oil Corporation Ltd (IOC), in November 2009 joined with NPCIL in an agreement "for partnership in setting up nuclear power plants in India," anticipating an amendment to the Atomic Energy Act in 2016. The initial plant envisaged was to be at least 1000 MWe, and NPCIL would be the operator and at least 51% owner. In November 2010 IOC agreed to take a 26% stake in Rajasthan 7&8 (2x700 MWe) as a joint venture, with the option to increase this to 49%. The estimated project cost is Rs 12,320 crore (123 billion rupees, $2.1 billion), and the 26% stake represented only 2% of IOC's capital budget in the 11th plan to 2012. The formal joint venture agreement was signed in January 2011.

The cash-rich Oil and Natural Gas Corporation (ONGC), which (upstream of IOC) provides some 80% of the country's crude oil and natural gas and is 84% government-owned, submitted a plan to collaborate with NPCIL in October 2017. The plan follows the government's amendment to the Atomic Energy Act 1962 to enable NPCIL to form joint ventures with public companies. It is expected that ONGC will become a minority partner with NPCIL on a number of present or planned 700 MWe PHWR projects.

Other plans and proposals

Indian Railways, with power requirement of 3000 MWe now and rising to 5000 MWe about 2022, also approached NPCIL to set up a joint venture to build two 500 MWe PHWR nuclear plants on railway land or existing nuclear sites for its own power requirements. The Railways already has a joint venture with NTPC – Bhartiya Rail Bijlee Company – to build a 1000 MWe coal-fired power plant at Nabi Nagar in Aurangabad district of Bihar, with the 250 MWe units coming on line 2014-15. The Railways also plans to set up another 2 x 660 MWe supercritical thermal power plant at Adra in Purulia district of West Bengal for traction supply at economical tariff. Some 23,500 km of its 65,000 km lines are electrified, and it spends 8000 crore ($1.34 billion) per year on power, at INR 5.4/kWh which it expects to reduce to INR 4.0/kWh (9 cents to 6.6 c).

In March 2017 NPCIL said it planned a joint venture with Indian Railways to set up nuclear power projects, but this is apparently not proceeding.

The Steel Authority of India Ltd (SAIL) and NPCIL were discussing a joint venture to build a 700 MWe PHWR plant. The site would be chosen by NPCIL, in Gujarat or elsewhere in western India.

In anticipation of the Atomic Energy Act amendment in 2016, Reliance Power Ltd, GVK Power & Infrastructure Ltd and GMR Energy Ltd were reported to be in discussion with overseas nuclear vendors including Areva, GE Hitachi, Westinghouse and Atomstroyexport.

In September 2009 the AEC announced a version of its planned Advanced Heavy Water Reactor (the AHWR-300 LEU) designed for export.

In August and September 2009 the AEC reaffirmed its commitment to the thorium fuel cycle, particularly thorium-based FBRs, to make the country a technological leader. However, little has happened on this front since then.

Overseas reactor vendors

As described above, there have been a succession of agreements with Russia's Atomstroyexport to build further VVER reactors. In March 2010 a 'roadmap' for building six more reactors at Kudankulam by 2017 and four more at Haripur after 2017 was agreed, bringing the total to 12. Associate company Atomenergomash (AEM) set up an office in India with a view to bidding for future work there and in Vietnam, and finalizing a partnership with an Indian heavy manufacturer, either L&T (see below) or another. A Russian fuel fabrication plant is also under consideration.

In February 2009 Areva (now Framatome) signed a memorandum of understanding with NPCIL to build two, and later four more, EPR units at Jaitapur, and a formal contract was expected but this did not proceed. This followed the government signing a nuclear cooperation agreement with France in September 2008.

In March 2009 GE Hitachi Nuclear Energy signed agreements with NPCIL and Bharat Heavy Electricals Ltd (BHEL) to begin planning to build a multi-unit power plant using 1350 MWe Advanced Boiling Water Reactors (ABWR). In May 2009 L&T was brought into the picture. In April 2010 it was announced that the BHEL-NPCIL joint venture was still in discussion with an unnamed technology partner to build a 1400 MWe nuclear plant at Chutka in Madhya Pradesh state, with Madhya Pradesh Power Generating Company Limited (MPPGCL) the nodal agency to facilitate the execution of the project.

In May 2009 Westinghouse signed a memorandum of understanding with NPCIL regarding deployment of its AP1000 reactors, using local components (probably from L&T).

After a break of three decades, Atomic Energy of Canada Ltd (AECL) was keen to resume technical cooperation, especially in relation to servicing India's PHWRs (though this would now be undertaken by Candu Energy), and there were preliminary discussions regarding the sale of an ACR-1000.

In August 2009 NPCIL signed agreements with Korea Electric Power Co (KEPCO) to study the prospects for building Korean APR-1400 reactors in India. This could proceed following bilateral nuclear cooperation agreements signed in October 2010 and July 2011.

The LWRs to be set up by these foreign companies are reported to have a lifetime guarantee of fuel supply.

However, foreign reactor suppliers have put most plans on hold due to the possible implications of India’s Civil Liability for Nuclear Damage Act 2010. See Nuclear liability section below.

Uranium

Uranium resources and mining

India's uranium resources are modest, with 292,867 tonnes of uranium as identified resources in situ*, 282,401 tU of this as reasonably assured resources in situ and 10,466 tonnes as inferred resources in situ (to $260/kgU) at January 2021 in the OECD NEA 'Red Book'. In July 2017, 229,499 tU was clamied by the DAE. These are all in a high-cost category, and India expects to import an increasing proportion of its uranium fuel needs. In 2013 it was importing about 40% of uranium requirements. In July 2015 record annual domestic production of 1252 t U3O8 (1062 tU) was reported. However, 2015 production was only 385 tU.

* 56% carbonate deposits, 25% metamorphite, 7% sandstone, 6% proterozoic unconformity, 4% metasomatic, 2% granite-related, and <1% paleo-quartz-pebble-conglomerate.

Uranium mines in India

Exploration is carried out by the Atomic Minerals Directorate for Exploration and Research (AMD).

Mining and processing of uranium is carried out by Uranium Corporation of India Ltd (UCIL), also a subsidiary of the Department of Atomic Energy (DAE), in Jharkhand near Calcutta. Common mills are near Jaduguda (2500 t/day) and Turamdih (3000 t/day, expanding to 4500 t/day). Jaduguda ore is reported to grade 0.05-0.06%U. All Jharkhand mines are in the Singhbhum shear zone, and all are underground except Banduhurang. Another mill is at Tummalapalle in AP, expanding from 3000 to 4500 t/day.

In 2005 and 2006 plans were announced to invest almost $700 million to open further mines: in Jharkand at Banduhurang, Bagjata and Mohuldih; in Meghalaya at Domiasiat-Mawthabah (with a mill); and in Telangana at Lambapur-Peddagattu (with mill 50km away at Seripally), both in Nalgonda district.

Most production is via acid leach, producing magnesium diuranate or uranium peroxide via ion exchange. At Tummalapalle alkaline leach is used to produce sodium diuranate.

Uranium resources (as of July 2017)

| State | Districts | Main deposits | Tonnes U |

| Andhra Pradesh | YSR | Tummalapalle | 120,229 |

| Guntur | Koppunuru | 2341 | |

| Kurnool | Kappatralla | ? | |

| Telangana | Nalgonda | Lambapur, Pedagattu, Chitrial | 15,731 |

| Jharkhand | E.Singhbhum | Jaduguda, Bhatin, Narwapahar, Turamidh, Banduhurang, Mohuldih, Bagjata, | 53,237 |

| Saraikela-Kharswan | Bangurdih | 1367 | |

| Meghalaya | West Khasi Hills | KPM (Domiasat), Wahkyn, Wahkut | 19,538 |

| Rajasthan | Sikar, Udaipur | Rohil, Umra | 7989 |

| Karnataka | Yadgir, S.Kanara | Gogi | 3970 |

| Chhattisgarh | Rajanandgaon, Surguja | Bodal, Jajawal | 3380 |

| Uttar Pradesh | Sonbhadra | Naktu | 666 |

| Uttarakhand | Rudraprayag | Pokhri-Tunji | 85 |

| Himachal Pradesh | Una, Shimla, Mandi | Rajpura | 665 |

| Maharashtra | Gondia | Mogarra | 301 |

| Total | 229,499 |

The Jaduguda mine in Jharkhand was closed in September 2014 due to expiry of its mining licence, but this was renewed a few weeks later by the state government, and in December the East Singhbhum government gave approval to resume mining, subject to clearance from the forestry department, which was still awaited at the end of 2015. The AMD quotes resources as 6816 tU (March 2014). Serious questions have been raised about health issues and environmental management.*

* To 2015, three separate health surveys were carried out by independent specialists. They concluded that alleged health effects were not caused by radiation. One medical team noted that the problems noted can be seen in any Indian village with similar socio-economic parameters. The radiation due to UCIL operations is negligible compared with natural background radiation.

In Jharkand, Banduhurang is India's first open cut mine and was commissioned in 2007. Bagjata is underground and was opened in December 2008, though there had been earlier small operations 1986-91. The Mohuldih underground mine was commissioned in April 2012. The new mill at Turamdih serving these mines was commissioned in 2008. It is 7 km from Mohuldih. Narwapahar and Bhatin are other underground mines in this area.

In Andhra Pradesh (AP) and Telangana there are three kinds of uranium mineralization in the Cuddapah Basin, including unconformity-related deposits in the north of it.

In the north of the Basin, in Telangana, the new northern inland state subdivided from Andhra Pradesh in 2013, the Lambapur-Peddagattu project in Nalgonda district 110 km southeast of Hyderabad has environmental clearance for one open cut and three small underground mines (based on some 6000 tU resources at about 0.1%U) but faces local opposition. The central government had approved Rs 637 crore for the project, with processing to be at Seripally, 54 km away in Nalgonda district. In 2014 UCIL was preparing to approach the state government and renew its federal approvals for the project. A further deposit near Lambapur-Peddagattu is Koppunuru, in Guntur district of AP, now under evaluation, and Chitrial.

In the south of the Basin, the Tummalapalle belt with low-grade strata-bound carbonate uranium mineralization is 160 km long, and appears increasingly prospective – the AMD reports 37,000 tU in 15 km of it and over 100,000 tU overall, extending down dip to 1000 metres. Some secondary mineralization is reported in the Srisailam sub-basin.

In August 2007 the government approved a new US$ 270 million underground mine and mill at Tummalapalle near Pulivendula in YSR (Cuddapah) district of Andhra Pradesh, 300 km south of Hyderabad. Its resources have been revised upwards by the AMD to 71,690 tU (March 2014) and its cost to Rs 19 billion ($430 million), and to the end of 2012 expenditure was Rs 11 billion ($202 million). First commercial production was in June 2012, using an innovative pressurized alkaline leaching process (this being the first time alkaline leaching is used in India). Production is expected to reach 220 tU/yr as sodium diuranate, and in 2013 mill capacity was being doubled at a cost of Rs 8 billion ($147 million). An expansion of or from the Tummalapalle project is the Kanampalle U project, with 38,000 tU reserves. Further southern mineralization near Tummalapalle are Motuntulapalle, Muthanapalle, and Rachakuntapalle. The AMD has applied for a uranium prospecting licence for Kappatralla in the Kurnool district of AP, between the YSR district and Telangana.

In Karnataka, to the west of north Cuddapah Basin, UCIL is planning a small underground uranium mine in the Bhima basin at Gogi in Gulbarga area from 2014, after undertaking a feasibility study, and getting central government approval in mid-2011, state approval in November 2011 and explicit state support in June 2012. A portable mill is planned for Diggi or Saidpur nearby, using conventional alkaline leaching. Total cost is about $135 million. Resources are 4250 tU at 0.1% (seen as relatively high-grade) including 2600 tU reserves, sufficient for 15 years mine life, at 127 tU/yr, from fracture/fault-controlled uranium mineralization. UCIL plans also to utilize the uranium deposits in the Bhima belt from Sedam in Gulbarga to Muddebihal in Bijapur.

In Meghalaya, close to the Bangladesh border in the South West Khasi Hills, the Kylleng-Pyndengsohiong-Mawthabah – KPM – (known formerly as Domiasiat) mine project (near Nongbah-Jynrin) is on private land in a high rainfall area and has also faced longstanding local opposition partly related to land acquisition issues but also fanned by a campaign of fearmongering. For this reason, and despite earlier state government support in principle, UCIL was unable to get approval from the state government for the KPM open cut mine, though pre-project development had been authorized on 422 ha. Earlier there was federal environmental approval in December 2007 for a proposed uranium mine and processing plant here and for the Nongstin mine. There is sometimes violent opposition by NGOs to uranium mine development in the West Khasi Hills, including at KPM/Domiasiat and Wakhyn, which have estimated resources of 9500 tU and 8000 tU respectively. Tyrnai is a smaller deposit in the area. The status and geography of all these is not known, beyond the AMD being reported as saying that UCIL is "unable to mine them because of socio-economic problems." In August 2016 the Meghalaya state government cancelled UCIL's lease in the South West Khasi Hills district to deliver a “strong message” against uranium mining in the state. At the end of 2016 the AMD called for tenders for 15,000 metres of exploration core drilling on the Nongiri Plateau in the South West Khasi Hills district. However in 2018 three AMD officials were assaulted whilst collecting uranium samples from small boreholes, prompting UCIL to close its project office in Meghalaya in August 2018 and terminate service agreements.

Fracture/fault-controlled uranium mineralization similar to that in Karnataka in the North Delhi Fold Belt is in the 130 km long Rohil belt in Sikar district in Rajasthan, with 6133 tU identified (March 2014).

The AMD reports further uranium resources in Chattisgarh state (3380 tU), Himachal Pradesh (665 tU), Maharashtra (300 tU), and Uttar Pradesh (750 tU).

In Jharkhand UCIL has a small project to recover uranium from copper tailings, near Hindustan Copper's Rakha and Surda mines.

India's uranium mines and mills – existing and planned

| State, district | Mine | Mill | Operating from | tU per year |

| Jharkhand | Jaduguda | Jaduguda | 1967 (mine) 1968 (mill) |

200 total from mill |

|---|---|---|---|---|

| Bhatin | Jaduguda | 1967 | ||

| Narwapahar | Jaduguda | 1995 | ||

| Bagjata | Jaduguda | 2008 | ||

| Jharkhand, East Singhbum dist. | Turamdih | Turamdih | 2003 (u/g mine) 2008 (mill) |

190 total from mill |

| Banduhurang | Turamdih | 2007 (open pit) | ||

| Mohuldih | Turamdih | 2012 | ||

| Andhra Pradesh, YSR district | Tummalapalle | Tummalapalle | 2012 2015 (mill) |

220 increasing to 330 |

| Andhra Pradesh, YSR district | Tummalapalle | Kanampalle? | 2017? | |

| Telangana, Nalgonda district | Lambapur-Peddagattu | Seripally/Mallapuram | 2024? (open pit + 3 u/g) | 130 |

| Karnataka, Yadgir (Gulbarga) district | Gogi | Diggi/Saidapur | 2020? (underground) | 130 |

| Meghalaya, West Khasi Hills district | Kylleng-Pyndeng-Sohiong-Mawthabah (KPM), (Domiasiat), Wakhyn | Mawthabah | suspended | 340 |

However, India has reasonably assured resources of 319,000 tonnes of thorium – about 13% of the world total, and these are intended to fuel its nuclear power program longer-term (see below). The AMD claims almost 12 million tonnes of monazite which might contain 700,000 tonnes of thorium.

In September 2009 largely state-owned Oil & Natural Gas Corporation ONCC proposed to form a joint venture with UCIL to explore for uranium in Assam, and was later reported to be mining uranium in partnership with UCIL in the Cauvery area of Tamil Nadu.

Uranium imports

Following an IAEA safeguards agreement, an NSG resolution and finally US Congress approval of a bilateral trade agreement in October 2008, two months later Russia's Rosatom and Areva from France had contracted to supply uranium for power generation, while Kazakhstan, Brazil and South Africa were preparing to do so. The Russian agreement was to provide fuel for PHWRs as well as the two small Tarapur reactors.

In February 2009 the actual Russian contract was signed with TVEL to supply 2000 tonnes of natural uranium fuel pellets for PHWRs over ten years, costing $780 million, and 58 tonnes of low-enriched fuel pellets for the Tarapur reactors. The 300 tU Areva shipment arrived in June 2009. RAPS 2 became the first PHWR to be fuelled with imported uranium, followed by units 5&6 there.

In January 2009 NPCIL signed a memorandum of understanding with Kazatomprom for the supply of 2100 tonnes of uranium oxide concentrate (UOC) over six years and a feasibility study on building Indian PHWR reactors in Kazakhstan. NPCIL said it represented "a mutual commitment to begin thorough discussions on long-term strategic relationship." The actual agreement in April 2011 covered 2100 tonnes by 2014. In March 2013 both countries agreed to extend the civil nuclear cooperation agreement past 2014. In 2015 the DAE renewed its contract for supply of 5000 tU from Kazatomprom over four years.

In September 2009 India signed uranium supply and nuclear cooperation agreements with Namibia and Mongolia. The latter was reaffirmed in May 2015, noting that Mongolian uranium “could help power India’s low-carbon growth.”

In March 2010 Russia offered India a stake in the Elkon uranium mining development in its Sakha Republic, and agreed on a joint venture with ARMZ Uranium Holding Co.

In August 2014 Navoi Mining and Metallurgical Combine (NMMC) in Uzbekistan signed a contract for supply of 2000 tonnes of U3O8 to India during the four years to 2018, its first export to India. A further contract was signed in January 2019, for long-term supply.

In September 2014 a bilateral safeguards agreement with Australia was signed, then came into force in November, enabling supply from there.

In April 2013 a bilateral safeguards agreement was signed between the DAE and the Canadian Nuclear Safety Commission (CNSC), and in April 2015 Cameco signed an agreement to supply 3200 tonnes of U3O8 (UOC) to India up to 2020. The first Cameco shipment arrived in December 2015.

In July 2015 the DAE reported to parliament that eight reactors (Kaiga 1-4, Madras 1&2 and Tarapur 3&4) were using indigenous sources of uranium and 14 reactors were using imported uranium. This situation was confirmed in July 2016 and July 2017.

In 2014 the DAE reported that India had imported 4458 tonnes of uranium since 2008 (2058 t from TVEL, 2100 t from Kazatomprom, and 300 t from Areva).

Uranium imports from 2014

| Year | Source | Form | Tonnes |

| 2014-15 | TVEL Kazatomprom |

UO2 pellets UOC |

297 283 |

| 2015-16 | Cameco TVEL |

UOC UO2 pellets |

251 346 |

| 2016-17 | Kazatomprom Cameco TVEL |

UOC UOC UO2 pellets |

1924 1234 187 |

Fuel cycle

India's main nuclear fuel cycle complex is at Hyderabad in Telangana, established in 1971. It plans to set up three more to serve the planned expansion of nuclear power and bring relevant activities under international safeguards. The first of the three will be at Kota in Rajasthan, supplying fuel for the 700 MWe PHWRs at Rawatbhata and Kakrapar by 2016. Capacity will be 500 t/yr plus 65 t of zirconium cladding. The second new complex will supply fuel to ten 700 MWe PHWRs planned in Haryana, Karnataka and Madhya Pradesh, but its site is not announced. The third will be at Chitradurga in the south of Karnataka state on a site with other science-based establishments, starting with a BARC enrichment plant, to supply fuel for light water reactors (see below).