Former Australian Uranium Mines

Appendix to Australian Uranium information paper

Australian Uranium Production from Mines now Permanently Closed

| mine | period | ore milled | grade U3O8 | production U3O8 |

| Radium Hill | 1954-62 | 970 000 t | 0.11-0.15% | 850 t |

| Rum Jungle | 1954-71 | 863 000 t | 0.27-0.43% | 3530 t |

| Mary Kathleen | 1958-63 | 2 900 000 t | 0.15%* | 4080 t |

| 1975-82 | 6 300 000 t | 0.10% | 4802 t | |

| Moline | 1959-64 | 128 000 t | 0.35-0.68% | 520 t |

| Rockhole | 1959-62 | 13 500 t | 1.12% | 138 t |

| Nabarlek | 1979-88 | 600 000 t | 2.0% | 10 858 t |

* Some Mary Kathleen ore was upgraded by radiometric ore sorting. See text.

Nabarlek

In 1959 Queensland Mines Ltd. was formed as a uranium exploration company. In May 1970 it discovered Nabarlek, a small high-grade deposit just inside Arnhem Land, 15 kilometres east of Oenpelli and in the East Alligator River region of the Northern Territory. Agreement was reached with the Northern Land Council and other Aboriginal groups to enable development of the deposit.

Queensland Mines opened Nabarlek in 1979. The Nabarlek 1 orebody was mined out in just over four months of the dry season and 600,000 tonnes of average 2% grade ore stockpiled for treatment from 1980. About 2.3 million tonnes of waste was also mined. A total of 10,858 tonnes of uranium oxide (U3O8) was produced at 1500 tonnes per year and sold to Japan, Finland and France, 1981-88. About $14 million was paid in aboriginal royalties.

Nabarlek then remained one of the three uranium mines approved under the ALP 'three mines policy' applied by the previous federal Labor government. Accordingly it had considerable value if further ore reserves were found on its leases, or even nearby.

The Nabarlek 2 deposit is of unknown, but apparently not great, significance. It is not described as an orebody.

However, Pioneer International Ltd as the parent company of Queensland Mines wrote off Nabarlek except for a liability in its balance sheet to allow for rehabilitation of the site. In respect to its exploration leases at Nabarlek it introduced Cogema Australia on a farm-in basis to undertake further exploration, and Cogema (now Areva) then had a 50% interest in these. Subsequently, Uranium Equities Ltd, which changed its name to Devex Resources, held the Nabarlek lease and the area around it. In 2018 Devex announced a geophysical “drill target” below the old open pit as part of its West Arnhem Project.

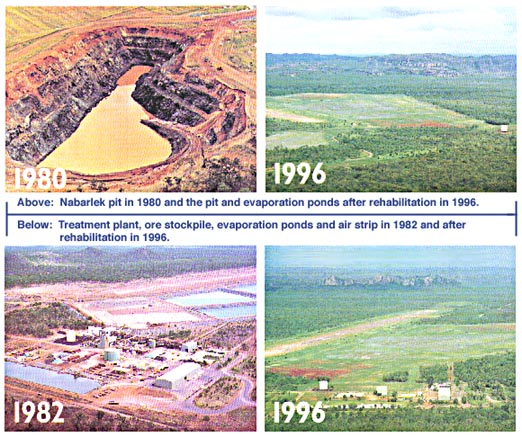

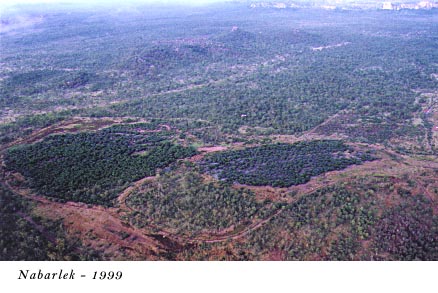

Part of the plant was sold in 1994. Before removal it was cleaned and decontaminated to very stringent standards chemically and radiologically. The remainder was dismantled and buried in the mine pit, with all tailings and evaporite, as well as building foundations. Waste rock completed the filling of the pit, and a layer of waste rock was applied over its surface as an erosion-resistant cover. Stockpiled topsoil completed the site landscaping earthworks. The whole area was then seeded with a mixture of grass and a wide range of native species in accordance with the authorised decommissioning plan. This work was completed at the end of 1995. The vegetation became well-established and there has been little erosion. Monitoring and research continue, as Nabarlek represents the first rehabilitation of a uranium mine according to current principles and practice.

The Nabarlek pit (right of centre) in February 1999, with the waste rock dump site on the left, looking west.

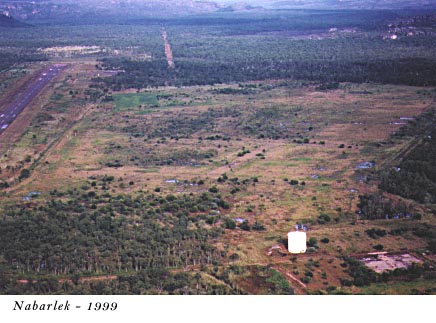

The Nabarlek plant, evaporation pond and ore stockpile site in February 1999

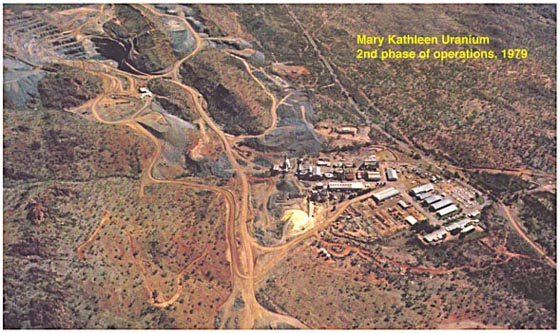

Mary Kathleen

Mary Kathleen is about half way between Mount Isa and Cloncurry, in far north west Queensland. The deposit was discovered in 1954 by prospectors from nearby Mount Isa. In 1955 Mary Kathleen Uranium Ltd (MKU) was formed, with a majority of the shares held by the Rio Tinto Mining Company of Australia Limited.

A sales contract with the United Kingdom Atomic Energy Authority was signed in 1956. Mining commenced at the end of 1956 and the treatment plant was commissioned in June 1958. The project was developed by MKU at a cost of A $24 million.

Beyond ascertaining that sufficient ore (at a grade of 0.16% ) was available to meet obligations under the UK contract, the orebody was not fully proved up at this stage. (Initial reserves were later quoted at 7 million tonnes of 0.12% ore containing 12,000 tonnes of U3O8.) However it was evident that the mineralisation (3.0% rare earth oxides and 0.025% thorium oxide) really comprised a rare earths orebody containing uranium, and over the years various attempts were made to find markets for the rare earths as a co-product, to no avail.

In this first phase of operation from 1958 to 1963 Mary Kathleen treated 2.9 million tonnes of ore at an average grade of 0.13% to yield 4082 tonnes of uranium concentrate (then actually yellowcake - ammonium diuranate) containing 3460 tonnes of uranium.

Initially the process was the conventional sequence of crushing, grinding, leaching with sulfuric acid, counter-current decantation, followed by ion exchange and extraction and drying. In 1960 electronic radiometric ore sorting was introduced to concentrate ore prior to crushing, with the result that the head grade feed increased from 0.17% to 0.24%.

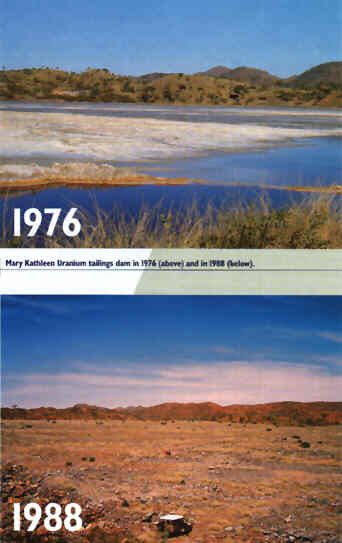

Tailings were emplaced in a 12 hectare tailings dam in a small valley west of the plant. This overflowed into an evaporation pond of some 60 hectares.

With improvements in the treatment plant the contract was filled faster than the nine years originally envisaged, and hence in October 1963 the mine closed and the plant was put on care and maintenance. Some 2.8 million tonnes of 0.148% ore was identified then as remaining accessible by open pit mining, containing 4246 tonnes of uranium oxide.

In the event, the mine remained closed for more than a decade. New contracts with utilities in Japan, Germany and USA for 4740 tonnes of uranium oxide were negotiated early in the 1970s and recommissioning began in 1974. The company made a share issue to raise capital, and the Commonwealth Government, through the Australian Atomic Energy Commission underwrote this, thereby obtaining a 42% holding in the company. Conzinc Riotinto of Australia Limited, a successor of Rio Tinto Mining, held 51%, and the public 7%.

In the plant the ion exchange section was replaced with a more effective solvent extraction process and the mine and mill reopened in February 1976. The cost of refurbishment was A $26 million.

At the end of 1982 the mine was depleted and finally closed down after 4802 tonnes of uranium oxide concentrate (4072 tU) had been produced in its second phase of operation. During the 12 years of operations about 31 million tonnes of material was mined, including 7 million tonnes of ore.

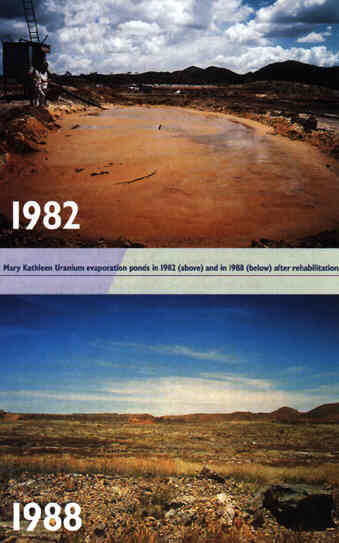

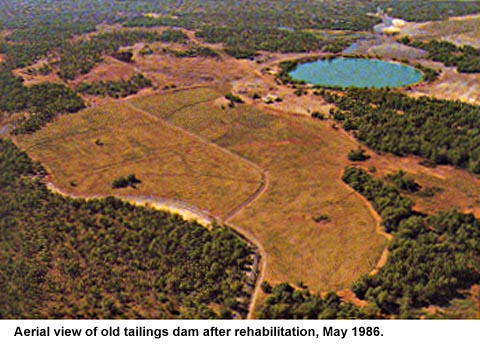

Notwithstanding the minimal conditions imposed in relation to the 1954 leases, the company took the view that it should conform to relevant current environmental and occupational health standards. Consequently, before the recommissioning in 1976 a full environmental impact study was undertaken and this incorporated a rehabilitation plan for the 64 hectares of waste dumps, 29 hectares of tailings dam and 60 hectares of evaporation ponds. Mary Kathleen then became the site of Australia's first major rehabilitation project of a uranium mine, which was completed at the end of 1985 at a cost of some A$ 19 million. In 1986 this work won an award from the Institution of Engineers Australia for environmental excellence.

Uranium Evaporation Ponds

Uranium Tailings

In the late 1980s, following relinquishment of the Mary Kathleen leases, MKU was liquidated.

Rum Jungle

The Rum Jungle uranium deposit was discovered in 1949 by a local prospector. It is 64 kilometres south of Darwin in the Northern Territory, on the East Finniss River.

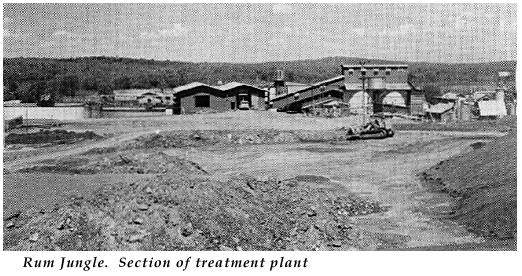

In March 1952 the Commonwealth Government provided funds for setting up a mine and treatment plant to provide uranium oxide concentrate to the UK-US Combined Development Agency (CDA) under a contract which ran from 1953 to 1962. Rum Jungle was then the largest industrial undertaking in the Northern Territory. The Commonwealth, through the Australian Atomic Energy Commission (AAEC), was responsible for the mine, though management of it was on a contract basis (cost plus) by Territory Enterprises Pty Limited, a subsidiary of Consolidated Zinc Pty Ltd* set up for that purpose. A new town was built at Batchelor, a major wartime air base some 8 kilometres south of the mine.

* In 1962 Consolidated Zinc merged with the Australian interests of Rio Tinto Company Ltd to form Conzinc Riotinto of Australia Limited.

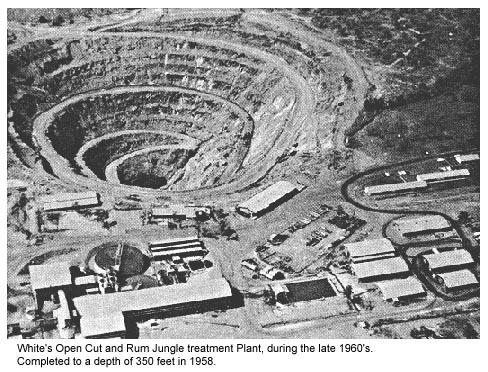

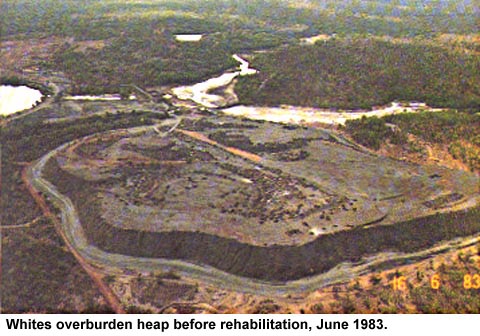

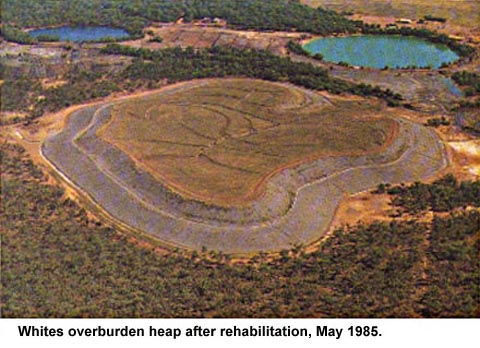

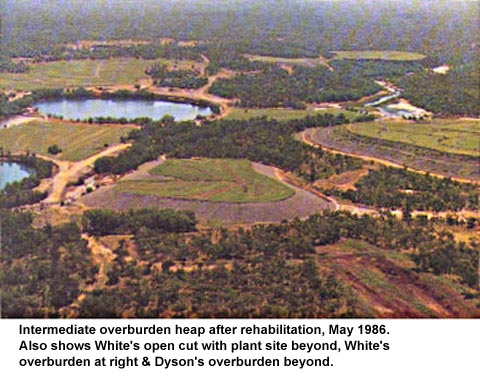

The White's orebody was initially developed underground, from 1950 to 1953. Production from White's open cut started in 1953 and the treatment plant commenced in 1954. White's was mined out to depth of over 100 metres in November 1958 and Dyson's open cut was mined in 1957-58. A little ore was mined in 1958 from Mt Burton open cut, 4 kilometres west of the plant. Ore from these was stockpiled and progressively treated, and was more than sufficient to complete the CDA contract.

Rum Jungle Creek South orebody some 7 kilometres south of the plant site and 3 kilometres west of Batchelor was discovered in 1960 by Territory Enterprises, but there was no sales contract for its uranium. However, in 1961 the Commonwealth Government decided to proceed with developing it. It was mined 1961-63 to depth of 67 metres, with the relatively high-grade (0.37% U) ore being stockpiled for treatment beyond the January 1963 expiry of the CDA contract. The product from this was to be offered on the open market or stockpiled at AAEC in Sydney until the market improved in the 1970s. In the event, about 2000 tonnes of uranium oxide concentrate was thus stockpiled by the time the mine closed in 1971.*

* In 1994, 239 tonnes on Rum Jungle uranium oxide was sold to a US utility, leaving 1814 tonnes still stockpiled.

Up to mid-1962, when the offer expired, the AAEC also purchased some high-grade uranium ore from other deposits for treatment at Rum Jungle. From 1954 to 1957 the Australian Uranium Corporation NL sold ore from its Adelaide River mine to AAEC, and in 1962 South Alligator Uranium NL sold some high grade ore from the Eva deposit near the Queensland border, 900 kilometres away, which yielded 6 tonnes of uranium oxide.

The uranium treatment plant used an acid leach and ion exchange process until 1962 when the latter section was replaced with solvent extraction and magnesia precipitation to treat the Rum Jungle Creek South ore. Tailings were released into a poorly engineered shallow dam initially and after 1958 were put into White's pit.

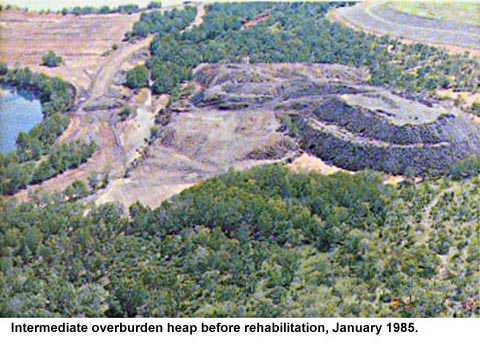

As well as uranium, mineralisation at Rum Jungle included copper and lead. Some ore from White's was treated to recover copper, and in addition the Intermediate orebody was mined to a depth of 68 metres in 1964-5 solely for copper by Australian Mining and Smelting Company Limited*, a subsidiary of Consolidated Zinc (later Conzinc Riotinto of Australia, later Rio Tinto). This necessitated the diversion of the East Finniss River. About 360,000 tonnes of mill grade ore at 2% or more copper was recovered with another 370,000 tonnes of leaching grade ore (0.7-2.0% Cu). The latter** was treated in heap leach from 1965.

*This AM&S is not the same as a later CRA company bearing the same name.

** The heap leach consisted of 260 000 t sulphide ore averaging 1.7% copper and 110 000 t oxide ore averaging 2.0% copper.

Rum Jungle treated 863,000 tonnes of 0.27-0.43% U3O8 ore to produce 3530 tonnes of U3O8, according to the most authoritative accounts, (along with 20,000 tonnes of copper concentrate from other ore). Others represent uranium oxide and copper concentrate as follows, though the uranium data and probably the copper refer to contained minerals rather than production:

| Ore | U3O8 | copper conc. | |

|---|---|---|---|

| (tonnes) | (tonnes) | (tonnes) | |

| White's (main) | 698 000 | 1088 | 17 000 |

| Dyson's | 157 000 | 534 | - |

| Intermediate | 360 000 | - | 10 000 |

| Rum Jungle Creek South | 665 000 | 2860 | - |

| Mt Burton | 6 000 | 13 | - |

Towards the end of the mine's life the AAEC undertook studies to identify the extent and degree of environmental damage and likely sources of pollution. However, on completion of mining in 1971 it was decided by the Commonwealth Government that funds should not be made available for any rehabilitation, so the area was simply left.

Within a few years the Rum Jungle mine had become one of Australia's most notorious pollution problems, due to oxidation of sulphides by bacteria and the consequent release of acid and metals into the East Finniss River – acid mine drainage (AMD). The monsoonal climate and 1500 mm rainfall coupled with the pyritic mineralisation in the area created ideal conditions for such processes (which of course were harnessed, without commercial success, in the copper leaching operation).

An initial attempt to clean up Rum Jungle was made in 1977, which led to the setting up of a working group to examine more comprehensive rehabilitation. A A$ 16.2 million Commonwealth-funded program got under way in 1983-88. A supplementary A$ 1.8 million program to improve Rum Jungle Creek South waste dumps was undertaken in 1990-91. Total cost was put at $18.6 million.

Although at the time of the 1980s works the objectives were deemed to have been achieved, the gradual deterioration of the original rehabilitation works has become evident and some acid mine drainage is reappearing. In light of this and given advances in best practice standards in mine closure and rehabilitation, in 2009 the NT and Commonwealth governments entered a four-year $7.048 million National Partnership Agreement (NPA) to undertake various studies to inform the development of an updated rehabilitation strategy, since that from the 1980s had not fully stood the test of time. Though it resulted in a dramatic improvement in the quality of the water coming off the site, more needed doing. A draft plan, involving input from the traditional owners, was submitted to the federal government in May 2013 and a project agreement was signed to progress further rehabilitation and in October 2017 a further project agreement was signed, with $10 million committed by the federal government.

Intermediate and Whites open pits with Intermediate overburden, late 1980s

Radium Hill & South Australia

In the 1930s ores were obtained from an underground mine at Radium Hill in eastern South Australia to recover minute amounts of radium for medical purposes. As a result a few hundred kilograms of uranium were also produced and used as a bright yellow pigment in glass and ceramics.

In 1954 the underground mine was recommissioned and then operated by the South Australian Government to satisfy a cost-plus contract signed by the Commonwealth and SA Governments with the UK-USA Combined Development Agency for delivery of uranium oxide over seven years.

The ore was concentrated at Radium Hill by heavy media separation and flotation to produce a concentrate containing about 0.7% uranium. The mineral form was mostly davidite, making it difficult to treat. This concentrate was railed 300 kilometres to a treatment plant at Port Pirie where it was subject to hot acid leaching. The plant was designed to produce 160 tonnes of uranium oxide per year and operated by the SA Department of Mines.

The mine operated from 1954 to 1961, with an output of 970,000 t of 0.09-0.13% ore and the treatment plant operated from 1956 to February 1962, treating presumably about 120,000 tonnes of the 0.59-0.76% U concentrate to produce 850 tonnes of U3O8. This was sold through the Combined Development Agency.

Another mine, Myponga, was 64 km south of Adelaide and in 1954-55 contributed just over a tonne of U3O8 from 340 tonnes of ore. The ore was treated at Port Pirie.

Prior to 1954 approximately 2000 t of ore was mined from Mount Painter as well as Radium Hill and the ore was processed to recover radium (for medical applications). A small amount of the uranium (amount not reported) was also recovered from these ores for use in ceramic glazes. However Geoscience Australia considers that this uranium production can be considered insignificant. During the first phase of Australia¹s uranium production (1954 to 1971) there was no uranium mining at Mount Painter.

Despite media reports in 1945 and 2006, and despite a request from the British Government in 1944, only kilogram quantities of U3O8 were obtained from Mount Painter in 1944-45 and these were not exported. The British government however paid for the exploratory program there at the time.

South Alligator mines

The first of these mines was discovered in 1953, and this was followed by a series of other discoveries. Two companies, United Uranium NL and South Alligator Uranium NL, were principally involved in the area, each with its own treatment plant drawing upon ore from different mines.

United Uranium NL negotiated a contract with the US Atomic Energy Commission for the sale of up to 200 tonnes of pitchblende ore and concentrate from the El Sharana mine. A concentrating plant began operation in October 1956 and some 150 tonnes of pitchblende concentrate containing 70 tonnes of uranium was produced in 1956-57 and was supplied through the Combined Development Agency. The residues from this, containing 1.15% (or 1.5%) U, were sold to the AAEC at Rum Jungle.

In 1958 the two companies contracted with the UK Atomic Energy Authority for the supply of uranium oxide from the South Alligator mines.

United Uranium then purchased the North Hercules gold plant at Moline, 50 kilometres east of Pine Creek (and about 65 kilometres from the South Alligator mines) and started converting it for acid leaching and solvent extraction of uranium oxide with magnesia precipitation. The plant was commissioned with an annual capacity of about 130 tonnes U3O8 in May 1959, by which time there was a substantial stockpile of ore awaiting treatment.

South Alligator Uranium NL was meanwhile continuing underground exploration at its Rockhole prospect, and in 1957 United Uranium discovered the Coronation Hill uranium orebody.

In 1958 South Alligator Uranium commenced construction of a small (about 50 tonnes U3O8 per year) treatment plant at Rockhole Creek, using the same process as at Moline. This was commissioned in September 1959. However, it quickly filled its 118 tonne contract with UKAEA, so the mine was closed in 1961 and treatment of the stockpiled high-grade ore was completed soon after.

However, the Rockhole Creek plant was reopened in June 1962 for three months to produce 24 tonnes of uranium oxide for sale on the open market. The plant was then sold and partly dismantled. A total of 13,500 tonnes of average 0.95% U (1.12% U3O8) ore had been treated by the plant.

In 1963 United Uranium treated 15,000 tonnes of 0.69% U3O8 ore at Moline, a little over half from underground workings at the El Sharana West mine and the balance from open cut mines including Coronation Hill (mined 1957-1964). Exploration continued, but reserves were dwindling and the company purchased all the NT mining titles and the plant from the former South Alligator Uranium.

The Moline uranium plant finally closed in August 1964, having completed its A$ 10 million contract with the UKAEA involving the supply of 520 tonnes of uranium oxide. It had treated 128,000 tonnes of 0.30-0.58% U (0.35-0.68% U3O8) ore in a little over five years. (The plant was then converted to extract gold from the uranium tailings, and this finished in October 1965.)