Nuclear-Powered Ships

- Nuclear power is particularly suitable for vessels which need to be at sea for long periods without refuelling, or for powerful submarine propulsion.

- Over 160 ships are powered by more than 200 small nuclear reactors.

- Most are submarines, but they range from icebreakers to aircraft carriers.

- In future, constraints on fossil fuel use in transport may bring marine nuclear propulsion into more widespread use. So far, exaggerated fears about safety have caused political restriction on port access.

Work on nuclear marine propulsion started in the 1940s, and the first test reactor started up in USA in 1953. The first nuclear-powered submarine, USS Nautilus, put to sea in 1955.

This marked the transition of submarines from slow underwater vessels to warships capable of sustaining 20-25 knots submerged for long periods, independent of needing air for diesel engines to charge batteries.

Nautilus led to the parallel development of further (Skate-class) submarines, powered by single pressurised water reactors, and an aircraft carrier, USS Enterprise, powered by eight Westinghouse reactor units in 1960. A cruiser, USS Long Beach, followed in 1961 and was powered by two of these early units. Remarkably, the Enterprise remained in service to the end of 2012.

By 1962 the US Navy had 26 nuclear submarines operational and 30 under construction. Nuclear power had revolutionised the Navy.

The technology was shared with Britain, while French, Russian and Chinese developments proceeded separately.

After the Skate-class vessels, reactor development proceeded and in the USA a single series of standardized designs was built by both Westinghouse and GE, one reactor powering each vessel. Rolls-Royce built Westinghouse-derived units for the UK Royal Navy submarines and then developed the design further to the PWR2.

Russia developed both PWR and lead-bismuth cooled reactor designs, the latter not persisting. Eventually four generations* of submarine PWRs were utilised, the last entering service in 1995 in the Severodvinsk class.

* 1955-66, 1963-92, 1976-2003, 1995 on, according to Bellona.

The largest submarines are the 26,500 tonne (34,000 t submerged) Russian Typhoon class, powered by twin 190 MWt PWR reactors, though these were superseded by the 24,000 t Oscar-II class (eg Kursk) with the same power plant.

The safety record of the US nuclear navy is excellent, this being attributed to a high level of standardisation in naval power plants and their maintenance, and the high quality of the Navy's training program. However, early Soviet endeavours resulted in a number of serious accidents – five where the reactor was irreparably damaged, and more resulting in radiation leaks. There were more than 20 radiation fatalities.* Nevertheless, by Russia’s third generation of marine PWRs in the late 1970s safety and reliability had become a high priority. (Apart from reactor accidents, fires and accidents have resulted in the loss of two US and about four Soviet submarines, another four of which had fires resulting in loss of life.) In the US, UK and French navies there has never been a nuclear plant accident.

* The K-19 accident at sea in 1961 due to cooling failure in an early PWR resulted in eight deaths from acute radiation syndrome (ARS) in repairing it (doses 7.5 to 54 Sv) and possibly more later as well as many high doses. The K-27 accident at sea in 1968 also involved coolant failure, this time in an experimental lead-bismuth cooled reactor, and nine deaths from ARS as well as high exposure by other crew. In 1985 the K-431 was being refuelled in Vladivostok when a criticality occurred causing a major steam explosion which killed ten workers. Over 200 PBq of fission products was released causing high radiation exposure of about 50 others, including ten with ARS.

Lloyd's Register shows about 200 nuclear reactors at sea, and that some 700 have been used at sea since the 1950s. Other sources quote 108 reactors in US naval vessels in mid-2019. More than 14,000 reactor years of nuclear marine operation have been accumulated, Russia claims 7000 of these, and the US Navy has 6200 rector-years to 2021, with 526 reactors.

In 2021 the World Associationof Nuclear Operators (WANO) extended its peer-level pre-startup reviews – a normal procedure for power plants – to Russian icebreakers.

Nuclear naval fleets

Russia built 248 nuclear submarines and five naval surface vessels (plus nine icebreakers) powered by 468 reactors between 1950 and 2003, and was then operating about 60 nuclear naval vessels. (Bellona gives 247 subs with 456 reactors 1958-95.) For operational vessels in 1997, Bellona lists 109 Russian submarines (plus four naval surface ships) and 108 attack submarines (SSN) and 25 ballistic missile ones apart from Russia.

At the end of the Cold War, in 1989, there were over 400 nuclear-powered submarines operational or being built. At least 300 of these submarines have now been scrapped and some on order cancelled, due to weapons reduction programmes*. Russia and the USA had over 100 each in service, with the UK and France less than 20 each and China six. The total today is understood to be about 150, including new ones commissioned**. Most or all are fuelled by high-enriched uranium (HEU).

* In 2007 Russia had about 40 retired submarines from its Pacific fleet alone awaiting scrapping. In November 2008 it was reported that Russia intended to scrap all decommissioned nuclear submarines by 2012, the total being more than 200 of the 250 built to date. Most Northern Fleet submarines had been dismantled at Severodvinsk, and most remaining to be scrapped were with the Pacific Fleet.

** Late in 2019: USA 70, Russia 40, China 19, UK 10, France 9, India 3.

India launched its first nuclear submarine in 2009, the 6000 dwt Arihant SSBN, with a single 85 MW PWR fuelled by HEU (critical in August 2013) driving a 70 MW steam turbine. It is reported to have cost $2.9 billion and was to be commissioned in 2016. The second and slightly larger Arihant-class SSBN, the INS Aridhaman, being built at the Ship Building Centre in Visakhapatnam, was launched in 2017 and is due to be commissioned by 2022. It will have a more powerful reactor. Another three Arihant-class vessels launched by 2023 and then six SSBNs twice the size of Arihant class and six nuclear SSNs are planned, the latter being approved by the government in February 2015. The SSNs will be a similar size to Arihant-class SSBN and powered by a new reactor being developed by BARC. India is also leasing an almost-new 7900 dwt (12,770 tonne submerged) Russian Akula II-class nuclear attack submarine for ten years from 2010, at a cost of $650 million: the INS Chakra, formerly Nerpa. It has a single 190 MWt VM-5/OK-659B (or OK-650B) PWR driving a 32 MW steam turbine and two 2 MWe turbogenerators. A second Akula-class lease has been arranged.

The USA has the main navy with nuclear-powered aircraft carriers, while both it and Russia have had nuclear-powered cruisers (USA: 9; Russia: 4). The USA had built 219 nuclear-powered vessels to mid-2010. All US aircraft carriers and submarines are nuclear-powered. (The UK’s new large aircraft carriers are powered by two 36 MW gas turbines driving electric motors.)

The US Navy has accumulated over 6200 reactor-years of accident-free experience involving 526 nuclear reactor cores over the course of 240 million kilometres, without a single radiological incident, over a period of more than 50 years. It operated 81 nuclear-powered ships (11 aircraft carriers, 70 submarines – 18 SSBN/SSGN, 52 SSN) with 92 reactors in 2017. There were 10 Nimitz-class carriers in service (CVN 68-77), each designed for 50-year service life with one mid-life refuelling and complex overhaul of their two A4W Westinghouse reactors*. The Gerald Ford class (CVN 78 on) has a similar hull and some 800 fewer crew and two more powerful Bechtel A1B reactors driving four shafts as well as the electromagnetic aircraft launch system. It has an expected service life of 90 years. The Ohio-class SSBNs have a service life of 42 years.

* The seventh such vessel overhaul after 25 years is the Stennis, taking 4.5 years and costing $2.99 billion. It involves major upgrades to the propulsion plant, to the flight deck, catapults, combat systems and the island superstructure.

The Russian Navy logged over 6500 nautical reactor-years to 2015. It appears to have eight strategic submarines (SSBN/SSGN) in operation and 13 nuclear-powered attack submarines (SSN), plus some diesel submarines. Russia announced that it would build eight new nuclear SSBN submarines in its plan to 2015. Its only nuclear-powered carrier project was cancelled in 1992. It has one nuclear-powered cruiser in operation and three others were being overhauled. In 2012 it announced that its third-generation strategic submarines would have extended service lifetimes, from 25 to 35 years.

In 2012 construction of a nuclear-powered deep-sea submersible was announced. This is based on the Oscar-class naval submarine and is apparently designed for research and rescue missions. It will be built by the Sevmash shipyard at Severodvinsk, which builds Russian naval submarines.

China has about 12 nuclear-powered submarines (about 8 SSN type-93 Shang class and type-95 Tang class, about 6 SSBN type-94 Jin class and type-96), and was building 21 more. In February 2013 China Shipbuilding Industry Corp (CSIC) received state approval and funding to begin research on core technologies and safety for nuclear-powered ships, with polar vessels being mentioned but aircraft carriers being considered a more likely purpose for the new development. Its first nuclear-powered submarine was decommissioned in 2013 after almost 40 years of service. In June 2018 China National Nuclear Corporation (CNNC) requested bids from shipbuilders for the country's first nuclear-powered icebreaker. (Its first domestically-built aircraft carrier Shandong is conventionally oil-powered.)

France has a nuclear-powered aircraft carrier and ten nuclear submarines (4 SSBN, 6 Rubis class SSN), with six Barracuda class SSN coming online from 2021, Suffren being the first.

The UK has 12 submarines, all nuclear powered (4 SSBN, 8 SSN).

The occupational radiation doses to crew of nuclear vessels in very small. US Naval Reactors’ average annual occupational exposure was 0.06 mSv per person in 2013, and no personnel have exceeded 20 mSv in any year in the 34 years to then. The average occupational exposure of each person monitored at US Naval Reactors' facilities since 1958 is 1.03 mSv per year.

Civil vessels

Nuclear propulsion has proven technically and economically essential in the Russian Arctic where operating conditions are beyond the capability of conventional icebreakers. The power levels required for breaking ice up to 3 metres thick, coupled with refuelling difficulties for other types of vessels, are significant factors. The nuclear fleet, with six nuclear icebreakers and a nuclear freighter, has increased Arctic navigation from 2 to 10 months per year, and in the western Arctic, to year-round. In 2020 Rosatom said it has accumulated 400 reactor-years of operating experience with icebreakers.

The icebreaker Lenin was the world's first nuclear-powered surface vessel (20,000 dwt), commissioned in 1959. It remained in service for 30 years to 1989, and was retired due to the hull being worn thin from ice abrasion. It initially had three 90 MWt OK-150 reactors, but these were badly damaged during refuelling in 1965 and 1967. In 1970 they were replaced by two 171 MWt OK-900 reactors providing steam for turbines which generated electricity to deliver 34 MW at the propellers. Lenin was retired in 1989 and is now a museum.

It led to a series of larger icebreakers, the six 23,500 dwt Arktika class, commissioned from 1975. These powerful vessels have two 171 MWt OK-900A reactors delivering 54 MW at the propellers and are used in deep Arctic waters. The Arktika was the first surface vessel to reach the North Pole, in 1977. Yamal, commissioned in 1992, remains in service, with Sibir, Arktika, Rossija and Sovetskiy Soyuz decommissioned in 1992, 2008, 2013 and 2014 respectively. Nominal service life was 25 years (150,000 hours for the reactors), but Atomflot first confirmed 30-year life for it, then in 2020 following a service life extension programme, a further 50,000 hours was licensed, representing six years to 2028. The original Arktika class were 148 m long and 30 m wide, and designed to break two metres of ice.

The sixth and largest Arktika-class icebreaker – 50 Years of Victory (50 Let Pobedy) – was built by the Baltic shipyard at St Petersburg and after delays during construction it entered service in 2007 (twelve years later than the 50-year anniversary of 1945 it was to commemorate). It is 25,800 dwt, 160 m long and 20 m wide, and is designed to break through ice up to 2.8 metres thick. Its propulsive power is about 54 MW.

For use in shallow waters such as estuaries and rivers, two shallow-draft Taymyr-class icebreakers of 18,260 dwt with one 171 MWt KLT-40M reactor delivering 35 MW propulsive were built in Finland and then fitted with their nuclear steam supply system in Russia. They – Taymyr and Vaygach – are built to conform with international safety standards for nuclear vessels and were launched in 1989 and 1990 respectively. They are 152 m long and 19 m wide, will break 1.77 metres of ice, and were expected to operate for about 30 years or 175,000 hours. OKBM Afrikantov was contracted to extend the operational lifetime of Vaygach to 200,000 hours, and the same was achieved for Taymyr. In 2021 Atomflot was working to extend the reactor life to 235,000 hours in both vessels.

In anticipation of decreasing ice and increased traffic, tenders were called for building the first of a new LK-60 series of Russian icebreakers in mid-2012, as Project 22220, and the contract was awarded to Baltijsky Zavod Shipbuilding in St Petersburg. The keel of the new Arktika was laid in November 2013, it was launched in June 2016 and it was due to be delivered to Atomflot by the end of 2017 at a cost of RUR 37 billion. In January 2013 Rosatom called for bids to build two more LK-60 icebreakers and a RUR 84.4 billion contract for the second and third vessels, Sibir and Ural, was let in May 2014 to the same shipyard, for delivery in 2019 and 2020. The project cost was quoted in mid-2016 at RUR 122 billion. Construction of the Sibir started in May 2015 and it was launched by the Baltic Shipyard in September 2017. The two RITM-200 reactors were installed at the end of 2017. A flag-raising ceremony was held for Sibir in January 2022 and the vessel has been escorting ships through ice in the Kara Sea and Gulf of Ob. Construction of Ural started in July 2016 and it was launched in May 2019. Arktika was expected to be in service in 2019 but the date was pushed back to April 2020 due to a delay in manufacturing the steam turbines. It commenced sea trials in December 2019, but in February 2020 one of its propulsion motors was damaged by a short circuit, requiring complex replacement undertaken in September-October 2021. In November 2022 a flag-raising ceremony marked the Ural's entry to service and it was sent to the Kara Sea the following month for operational icebreaking. Construction of the fourth LK-60, Yakutia, started in mid-2020. In November 2022 the Yakutia was launched into the water with a completed hull and is expected to be commissioned in 2024. Construction of the fifth icebreaker of Project 22220, Chukotka, began at the end of 2020 and is scheduled to be operational by the end of 2026. In total Russia plans to build seven vessels of this type with five either completed or under construction. Intended service life is 40 years. In February 2023 an agreement was signed between Baltic Shipyard and Atomflot for the construction of two more nuclear-powered icebreakers. The icebreakers have 60 MW of power (on shafts) and 40 years of expected service life, with commissioning scheduled for December 2028 and December 2030.

The LK-60 vessels are 'universal' dual-draught (10.5 m with full ballast tanks, minimum 8.55 m), displacing up to 33,540 t (25,450 t without ballast), for use in the Western Arctic year-round and in the eastern Arctic in summer and autumn. They are 173 m long, 34 m wide, and designed to break through 2.8 metre thick ice at up to 2 knots. Top speed is 22 knots. The wider 33 m beam at the waterline is to match the 70,000 tonne ships they are designed to clear a path for, though a few ships with reinforced hulls are already using the Northern Sea Route. There is scope for more use: in 2011, 19,000 ships used the Suez Canal and only about 40 traversed the northern route. This increased in 2013 – see below.

The LK-60 is powered by two RITM-200 reactors of 175 MWt each which together deliver 60 MW at the three propellers via twin turbine-generators and three electric motors. The LK-60 is designed to operate in the western Arctic – in the Barents, Pechora and Kara Seas, as well as in shallow water of the Yenissei river and Ob bay, for year-round pilotage (also as tug) of tankers, dry-cargo ships and vessels with special equipment to mineral resource development sites on the Arctic shelf. The Yamal LNG project is expected to need 200 shipping movements per year from Sabetta at the mouth of the Ob river. The vessel has a smaller crew than its predecessors – only 53. They will replace the older vessels Sovetskiy Soyuz and Yamal.

A more powerful Russian LK-120 (originally LK-110) icebreaker, Project 10510, Lider (or Leader), will be powered by two RITM-400 reactors of 315 MWt each to deliver 120 MW propulsion through four 37 MW turbine-generators, four electric motors and four propellers. It is to be capable of breaking through 4.3 metre thick ice at 2 knots, or 2 m thick ice at 15 knots. It is for deep-sea use in the eastern Arctic and will be 209 m long, 50 m wide and with 13 m draft, with displacement of 69,700 dwt. Each of three planned vessels would have a crew of 127. Since they are too big for the St Petersburg shipyard, they are being built by the Zvezda Shipyard Complex in the Far East Primorye region near Vladivostok. Each vessel is expected to cost RUR 120 billion ($1.8-2.0 billion). A contract for the first one, Rossiya, was signed in April 2020, and the keel was laid in mid-2021. Commissioning is expected in 2028.

The LK-60 is too big for easy operation around the oil and gas fields, so Project 10570 is under development with an LK-40 intended for shallow water and the Arctic shelf, with a range of uses. It will displace 20,700 t and be 152 m long, 31 m wide, draft 8.5 m, using a single RITM-200B reactor of 209 MWt delivering 40 MW at the propellers. The reactor plant mass is 1453 tonnes.

Development of nuclear merchant ships began in the 1950s but on the whole has not been commercially successful. The 22,000 tonne US-built NS Savannah, was commissioned in 1962 and decommissioned eight years later. The reactor used 4.2% and 4.6% enriched uranium. It was a technical success, but not economically viable. It had a 74 MWt reactor delivering 16.4 MW to the propeller, but the reactor was uprated to 80 MWt in 1964. The German-built 15,000 tonne Otto Hahn cargo ship and research facility sailed some 650,000 nautical miles on 126 voyages in 10 years without any technical problems. It had a 36 MWt reactor delivering 8 MW to the propeller. However, it proved too expensive to operate and in 1982 it was converted to diesel.

The 8000 tonne Japanese Mutsu was the third civil vessel, put into service in 1970. It had a 36 MWt reactor delivering 8 MW to the propeller. It was dogged by technical and political problems and was an embarrassing failure. These three vessels used reactors with low-enriched uranium fuel (3.7-4.4% U-235).

In 1988 the NS Sevmorput was commissioned in Russia, mainly to serve northern Siberian ports. It is a 61,900 tonne 260 m long LASH-carrier (taking lighters to ports with shallow water) and container ship with ice-breaking bow capable of breaking 1.5 metres of ice. It is powered by a KLT-40 reactor similar to the OK-900 as used in larger icebreakers, but with only 135 MWt power delivering 32.5 propeller MW. It needed refuelling only once to 2003. It was to be decommissioned about 2014, but Rosatom approved overhauling it and the ship was returned to service in 2015. In 2019 it was used to ship fresh food from the Pacific across the northern sea route to Murmansk.

Russian experience with nuclear powered Arctic ships totals about 400 reactor-years to 2021. In 2008 the Arctic fleet was transferred from the Murmansk Shipping Company under the Ministry of Transport to Atomflot, under Rosatom. This became a commercial enterprise, with the 40% state subsidy of RUR 1262 million in 2011 phased out in 2014.

In August 2010 two Arktika-class icebreakers escorted the 100,000 dwt tanker Baltika, carrying 70,000 tonnes of gas condensate, from Murmansk to China via the Northern Sea Route (NSR), saving some 8000 km compared with the Suez Canal route. In November 2012 the Ob River LNG tanker with 150,000 cubic metres of gas as LNG, chartered by Russia's Gazprom, traversed the northern sea route from Norway to Japan accompanied by nuclear-powered icebreakers, the route cutting 20 days off the normal journey and resulting in less loss of cargo. It has a strengthened hull to cope with the Arctic ice. There are plans to ship iron ore and base metals on the northern sea route also.

In 2013 the Atomflot icebreakers supported freight transportation and emergency rescue operations along the Northern Sea Route (NSR), and freezing northern seas and estuaries of rivers. In the framework of the regulated activity paid for as per rates established by the Federal Tariff Service of Russia (FST), 151 steering operations were carried out for ships with cargo and in ballast to and from ports in the aquatic area of the NSR, including steering of ships with cargo for building Sabetta Port of JSC Yamal SPG to Okskaya Bay and steering of a convoy of Navy ships under a contract with the Ministry of Defence. Over the 2013 summer-autumn navigation season, 71 transit steering operations were carried out, including 25 foreign-flag ships. A total of 1,356,000 tonnes of various cargoes was shipped east and west through the aquatic area of the NSR.

In 2017 the World Association of Nuclear Operators (WANO) for the first time carried out a corporate peer review of Atomflot, focused on safety culture. WANO routinely carries out such reviews of nuclear power plants worldwide.

Nuclear power and propulsion systems

Naval reactors (with the exception of the ill-fated Russian Alfa class described below) have been pressurised water types, which differ from commercial reactors producing electricity in that:

- They deliver a lot of power from a very small volume and therefore most run on highly-enriched uranium (>20% U-235, originally c 97% but apparently now 93% in latest US submarines, c 20-25% in some western vessels, 20% in the first and second generation Russian reactors (1957-81)*, then 21% to 45% in 3rd generation Russian units (40% in India's Arihant). Newer French reactors run on low-enriched fuel.

- The fuel is not UO2 but a uranium-zirconium or uranium-aluminium alloy (c15%U with 93% enrichment, or more U with less – eg 20% – U-235) or a metal-ceramic (Kursk: U-Al zoned 20-45% enriched, clad in zircaloy, with c 200kg U-235 in each 200 MW core).

- They have long core lives, so that refuelling is needed only after 10 or more years, and new cores are designed to last 50 years in carriers and 30-40 years (over 1.5 million kilometres) in most submarines, albeit with much lower capacity factors than a nuclear power plant (<30%).

- The design allows for a compact pressure vessel with internal neutron and gamma shield. The Sevmorput pressure vessel for a relatively large marine reactor is 4.6 m high and 1.8 m diameter, enclosing a core 1 m high and 1.2 m diameter.

- Thermal efficiency is less than in civil nuclear power plants due to the need for flexible power output, and space constraints for the steam system.

- There is no soluble boron used in naval reactors (at least US ones) but boron may be a burnable neutron poison in the fuel.

- A submarine reactor is required to withstand the shock and vibration experienced by all warships in active service due to ocean turbulence and enemy action.

* An IAEA Tecdoc reports discharge assay of early submarine used fuel reprocessed at Mayak being 17% U-235.

The long core life is enabled by the relatively high enrichment of the uranium and by incorporating a 'burnable poison' such as gadolinium – which is progressively depleted as fission products and actinides accumulate and fissile material is used up. These accumulating poisons and fissile reduction would normally cause reduced fuel efficiency, but the two effects cancel one another out.

However, the enrichment level for newer French naval fuel has been dropped to 7.5% U-235, the fuel being known as 'Caramel', originally developed for research reactors and providing the possibility for greater fuel density, so helping to minimize the increased size of an LEU-fuelled core. It needs to be changed every ten years or so, but avoids the need for a specific military enrichment line, and some reactors will be smaller versions of those on the Charles de Gaulle. In 2006 the Defence Ministry announced that Barracuda class submarines would use fuel with "civilian enrichment, identical to that of EdF power plants," about 5% enriched, and certainly marks a major change there.

Long-term integrity of the compact reactor pressure vessel is maintained by providing an internal neutron shield. (This is in contrast to early Soviet civil PWR designs where embrittlement occurs due to neutron bombardment of a very narrow pressure vessel.)

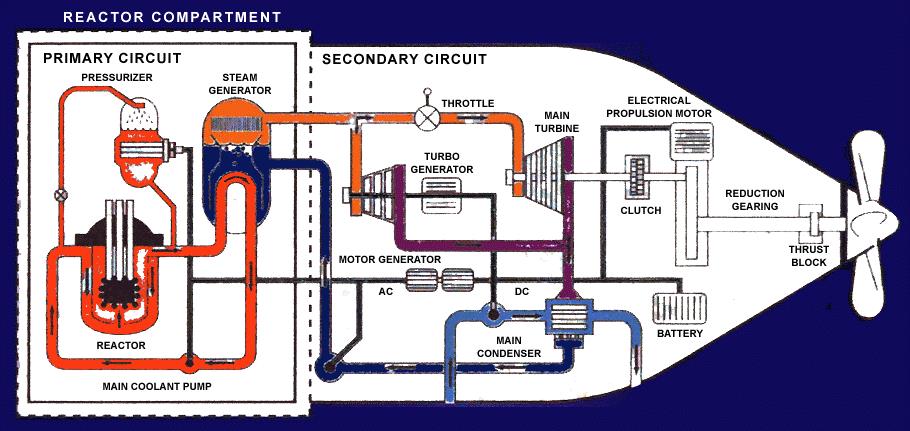

The Russian, US, and British navies rely on steam turbine propulsion, the French and Chinese in submarines use the turbine to generate electricity for propulsion.

Russian ballistic missile submarines as well as all surface ships since the Enterprise are powered by two reactors. Other submarines (except some Russian attack subs) are powered by one. A new Russian test-bed submarine is diesel-powered but has a very small nuclear reactor for auxiliary power.

Early Russian submarines were powered by VM-A PWRs using 20-21% enriched uranium fuel and producing 70 MWt. These had full-power core life of 1440 hours. The VM-2 then VM-4 reactors, also using 20% enriched fuel and most producing 90 MWt, followed it in second-generation Russian submarines, with twin units in larger vessels. Twin VM-5 PWRs, each 190 MWt and delivering 37 shaft MW, powered the third-generation SSBN vessels, with a single unit in the SSNs. The small Losharik submarine (Project 210, AS-12) is a specialist vessel capable of reaching great depths and has an E-17 PWR reactor.

Seven Russian Alfa-class submarines had a single liquid metal-cooled BM-40A or OK-550 fast neutron reactor of 155 MWt and using very highly enriched uranium – 90% enriched in U-Be fuel. The steam generator delivered 30 shaft MW. These vessels with titanium hulls were very fast, but had operational problems in ensuring that the lead-bismuth coolant did not freeze (at 125°C) when the reactor was shut down. Reactors had to be kept running, even in harbour, since the external heating provision did not work. The design was unsuccessful and all the vessels were retired early – the lead vessel in 1974 and all but one of the others in 1990. The reactor of the last vessel to be retired (K-123, redesignated B-123 in 1992) was replaced with a VM-4 PWR following a 1982 accident where liquid metal coolant leaked into the steam generator.

Russia’s K-27 was an experimental predecessor to the Alfa class with twin VT-1 or RM-1 lead-bismuth cooled reactors. After a few years' service it suffered a multi-fatality reactor accident in 1968, was laid up at Gremikha Bay, then scuttled in 1979. It now needs to be raised and dismantled there.

Russian cruisers have used twin KN-3 reactors of 300 MWt.

The US Navy's 1955 Nautilus had a S2W PWR with 93%-enriched fuel, 900-hour core life at full power delivering 10 MW shaft power. Its second nuclear submarine, USS Seawolf, SSN-575, had a sodium-cooled S2G power plant and operated for nearly two years (1957-58) with this. The intermediate-spectrum reactor raised its incoming coolant temperature over ten times as much as the Nautilus' water-cooled plant, providing superheated steam, and it offered an outlet temperature of 454°C, compared with the Nautilus’ 305°C. It was highly efficient, but offsetting this, the plant had serious operational disadvantages. Large electric heaters were required to keep the plant warm when the reactor was down to avoid the sodium freezing. The biggest problem was that the sodium became highly radioactive, with a half-life of 15 hours, so that the whole reactor system had to be more heavily shielded than a water-cooled plant, and the reactor compartment couldn’t be entered for many days after shutdown. The reactor was replaced with a PWR type (S2Wa) similar to Nautilus.

For many years the Los Angeles-class submarines built 1972-96 formed the backbone of the US SSN (attack) fleet, and 62 were built. They are 7000 dwt submerged, and have a 165 MW GE S6G reactor driving two 26 MW steam turbines. No refuelling is required for the 33-year service life. About one-third of these are now retired.

The Seawolf SSN in service from 1997 has an S6N reactor driving 34 MW pump-jet propulsion. They are about 9300 dwt submerged and require no refuelling during their 30-year service life. Only three (of 29 planned) were built to 1995, due to the high cost – $3.5 billion each.

The smaller US Virginia-class SSN submarine first commissioned in 2004 has has a S9G reactor of about 210 MWt driving a 30 MW pump-jet propulsion system built by BAE Systems (originally for the Royal Navy). The reactor does not need refuelling for the 33-year service life and can operate with convection circulation without pumps. The vessels are about 7900 dwt submerged, and 19 were in operation by mid-2021, with more being built – a total of 28 from initial contracts. In 2019 ten larger Block V versions (25 m longer, 10,800 dwt) were ordered for delivery 2025-29, costing $22.2 billion for the first nine. These are effectively a new class.

The 14 US Ohio-class SSBNs (and four converted to SSGNs for guided missiles) have a single S8G nuclear reactor of 220 MWt delivering 45 MW shaft power. These require mid-life refuelling at about 25 years. The 12 slightly larger Columbia class to replace these will require no refuelling, hence shorter mid-life maintenance (2 years instead of 4). They will have an S1B nuclear reactor with electric drive (without reduction gears) and pump jet propulsion. They have been developed in collaboration with the UK, which will deploy them as Dreadnought-class SSBNs.

In April 2021 BWX Technologies was awarded $2.2 billion in contracts for reactor components for Virginia- and Columbia-class vessels, over eight years.

Unlike PWRs, boiling water reactors (BWRs) circulate water which is radioactive* outside the reactor compartment, and are also considered too noisy for submarine use.

* Radioactivity in the cooling water flowing through the core is mainly the activation product nitrogen-16, formed by neutron capture from oxygen. N-16 has a half-life on only 7 seconds but produces high-energy gamma radiation during decay.

Reactor power ranges from 10 MWt (in a prototype) up to 200 MWt in the larger submarines and 300 MWt in surface ships such as the Kirov-class battle cruisers. A figure of 550 MWt each is quoted for two A4W units in Nimitz-class carriers, and these supply 104 shaft MW each (USS Enterprise had eight A2W units of 26 shaft MW and was refuelled three times). The Gerald Ford-class carriers have more powerful and simpler A1B reactors* reported to be at least 25% more powerful than A4W, hence about 700 MWt, but running a ship which apart from the steam turbnine propulsion is entirely electrical, including an electromagnetic aircraft launch system or catapult. Accordingly, the ship has about three times the electrical capacity of Nimitz-class. Ford-class A1B reactors are designed to be refuelled in mid-operational life of 50 years.

* This is a ‘Bechtel’ reactor since it has taken over Bettis Atomic Power Laboratory from Westinghouse, and Knolls Atomic Power Laboratory from GE. These have always provided naval power reactors.

The smallest nuclear submarines are the six French Rubis-class attack submarines (2600 dwt) in service since 1983, and these use a CAS48 reactor, a 48 MW integral PWR reactor from Technicatome (now Areva TA) with 7% enriched fuel that requires refuelling every 7-10 years.

The French aircraft carrier Charles de Gaulle (38,000 dwt), commissioned in 2000, has two K15 integral PWR units of 150 MWt scaled up from the CAS48 design driving 61 MW Alstom turbines and the system can provide five years running at 25 knots before refuelling.

The Le Triomphant class of ballistic missile submarines (14,335 dwt submerged – the last launched in 2008) uses these K15 naval PWRs of 150 MWt and 32 shaft MW with electric drive and pump-jet propulsion and operating cycle 20-25 years.

The Barracuda-class (5300 dwt submerged) or Suffren-class attack submarines have hybrid propulsion: electric for normal use and pump-jet for higher speeds. Areva TA (formerly Technicatome) supplies 150 MWt reactors based on the K15 for the six Barracuda submarines, delivering about 21.5 MW shaft power. The first was due to be commissioned in 2020. Refuelling interval is about ten years. As noted above, they will use low-enriched fuel – about 5-6%.

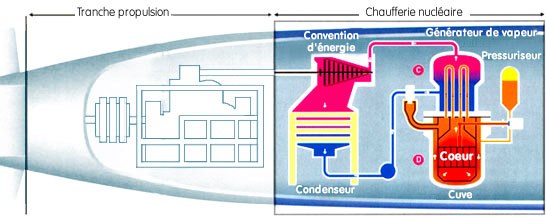

French integral PWR system for submarine

(steam generator within reactor pressure vessel)

UK: The Rolls-Royce PWR1 of about 78 MWt was used to power the first 23 British nuclear submarines. It was based on the Westinghouse S5W reactor, one of which was provided by the US Navy in 1958 under a mutual defence agreement. The PWR1 with high-enriched fuel required refuelling every ten years or so. The four British Vanguard-class ballistic missile submarines (SSBNs) of 15,900 dwt submerged have a single PWR2 reactor with two steam turbines driving a single pump jet of 20.5 MW, implying a reactor power of about 145 MWt.

UK Astute-class attack submarines of 7400 dwt submerged also have a PWR2 reactor of 145 MWt driving two steam turbines and a single pump-jet of 20.5 MW. The first of seven vessels was commissioned in 2010, and five were delivered by mid-2021 at a cost of £1.65 billion each. New versions of this with 'Core H' will require no refuelling over the life of the vessel, about 25 years*. In March 2011 a safety assessment of the PWR2 design was released showing the need for improvement, though they have capacity for passive cooling to effect decay heat removal.

* Rolls-Royce claims that the Core H PWR2 has six times the (undisclosed) power of its original PWR1 and runs four times as long. The Core H is Rolls-Royce's sixth-generation submarine reactor core.

The PWR3 for the Vanguard replacement Dreadnought-class SSBNs will be largely a US design – presumably based on the 210 MWt S9G in the Virginia-class – but using UK technology. It will be more expensive to build but cheaper to maintain than the PWR2. All UK submarine reactors use highly-enriched fuel, obtained from the USA.

Russia: Since 1959 Russia has used four generations of PWRs in its civil fleet:

- OK-150 in the Lenin until 1966 (3x90 MWt).

- OK-900 subsequently in the Lenin (2x159 MWt), OK-900A in the main Arktika-class icebreaker fleet (2x171 MWt).

- KLT-40 in the Sevmorput (1x135 MWt), KLT-40M in two Tamyr class icebreakers (1x171 MWt), and KLT-40S (2x35 MWe) in the Akademik Lomonosov floating nuclear power plant (FNPP).

- RITM-200 in the LK-60 generation of icebreakers (2x175 MWt), RITM-200M in the second generation FNPP (2x50-55 MWe), and the RITM-400 under development for LK-120 icebreakers (2x315 MWt). The RITM-200B (209 MWt) is also being developed for smaller icebreakers.

The OK series of reactors was developed separately from VVER power reactors, by OKBM Afrikantov. They were originally designed not to be refuelled. The KLT and RITM designs are also from OKBM-Afrikantov.

Russia's main submarine power plant is the VM-5 PWR with OK-650 steam generator unit of 190 MWt, using 20-45% enriched fuel. This set-up is usually known simply as an OK-650 nuclear power system. The large ballistic missile submarines (SSBNs) and cruise missile submarines have two of these with steam turbines together delivering 74 MW, and its third-generation attack submarines (SSN) have a single VM-5 plus OK-650 unit powering a 32 MW steam turbine.

The fourth-generation Borei-class SSBN with single 195 MWt OK-650 power plant is the first Russian design to use pump-jet propulsion. A fifth generation naval reactor is reported to be a super-critical type (SCWR) with single steam circuit and expected to run 30 years without refuelling. A full-scale prototype was being tested early in 2013.

Russia’s Project 885 Yasen-M class SSGN is said to be equivalent to the US Virginia class and will replace the Akula class. It is 13,800 dwt displacement and has a KTP-6 nuclear reactor of about 200 MW, an integral PWR. The Yasen class used a OK-650 system.

Russia's large Arktika-class icebreakers launched 1975-2007 use two OK-900A (essentially KLT-40M) nuclear reactors of 171 MW each with 241 or 274 fuel assemblies of 45-75% enriched fuel as U-Zr alloy and 3-4 year refuelling interval. They drive steam turbines and each produces up to 33 MW at the propellers, though overall propulsive power is about 54 MW. The two Tamyr class icebreakers have a single 171 MW KLT-40M reactor giving 35 MW propulsive power. Sevmorput uses one 135 MW KLT-40 unit producing 32.5 MW propulsive, and all those use 90% enriched fuel. (The now-retired Lenin's first OK-150 reactors used 5% enriched fuel but were replaced by OK-900 units with 45-75% enriched fuel.)

Most of the Arktika-class vessels have had operating life extensions based on engineering knowledge built up from experience with Arktika itself. It was originally designed for 100,000 hours of reactor life, but this was extended first to 150,000 hours, then to 175,000 hours. In practice this equated to a lifespan of eight extra years of operation on top of the design period of 25. In that time, Arktika covered more than 1 million nautical miles.

For the next LK-60 generation of Russian icebreakers, OKBM Afrikantov developed a new reactor – RITM-200 – to replace the KLT design. Under Project 22220 this is an integral 175 MWt, 53 MWe PWR with inherent safety features and using low-enriched uranium fuel (almost 20%) in 199 cermet fuel assemblies. Two reactors drive two turbine generators and then three electric motors powering the propellers, producing 60 MW propulsive power. Refuelling cycle quoted at 6-7 years, or at 65% capacity factor refuelling is every 7-10 years, overhaul at 20 years, over a 60-year operating lifetime. TVEL started making the fuel in 2016, with 4.5 TWh service life from each load (which would be 42% capacity over 7 years), but in 2020 the quoted service life is 7 TWh or 75,000 hours. The mass of two units is 2200 tonnes. The first icebreaker to be equipped with these (Arktika, named after the lead Arktika-class icebreaker) was launched in 2016 and finished commissioning in 2020. The design concept allows for a third reactor to feed into motive power. The reactors with four integral steam generators (12 cassettes) are made by ZiO-Podolsk.

The RITM-200B is a version for single use in smaller icebreakers. It is 209 MWt and produces 40 MW propulsive power. Its dimensions are 6x7x16 metres and mass is 1453 tonnes. Service life is 40 years.

The barge-based version is the RITM-200M (see floating nuclear power plants section below). The land-based version is the RITM-200N.

The integral RITM-400 reactors powering the LK-120 icebreakers will be 315 MWt, 120 MWe each with two delivering 120 MW propulsion through four electric motors. Core energy content is 6.0 TWh over service life before renovation at 160,000 hours, with 10-year refuelling interval. The fuel is a new design.* The reactor plant mass will be 3920 tonnes for two and their containment will be 8.2 x 9 x 17 metres each. Service life is 40 years.

* Rosatom reports: "Unlike RITM-200 reactors that have hexagonal fuel assemblies with spacer grids and cylindrical fuel rods, RITM-400 units will have a channel-type core with cylindrical-shaped fuel assemblies and self-spacing complex-profile fuel elements."

The KLT-40S is a four-loop version of the icebreaker reactor for floating nuclear power plants which runs on low-enriched uranium (<20%) and has a bigger core (1.3 m high instead of 1.0 m) and a shorter refuelling interval of 3-4.5 years. A variant of this is the KLT-20, specifically designed for floating nuclear power plants. It is a two-loop version with the same enrichment but a 10-year refuelling interval.

OKBM has supplied 460 nuclear reactors for the Russian navy, and these have operated more than 6500 reactor-years.

Russia’s planned Shtorm aircraft carrier (Project 23000) will be fitted with RITM-200 reactors.

China developed its first submarine nuclear power plant in the 1970s, with some Russian help. The two-loop 300 MWe Qinshan reactor commissioned in 1994 is said to be based on early submarine reactors. The Type 91 Han-class SSN and Type 92 Xia class had a single PWR of about 58 MWt, probably based on Russia’s OK-150 and delivering about 8.2 MW shaft power. The Type 93 Shang-class SSN and Type 94 Jin-class SSBN have one or two PWRs of about 150-175 MWt total delivering about 25 MW shaft power. The Type 95 SSN and Type 96 Tang-class SSBN have improved reactors possibly with reverse-engineering from US civil equipment, but little is known of them. At least in earlier reactors, China is believed to use low-enriched uranium fuel.

India's Arihant (6000 dwt) SSBN has an 82.5 MWe PWR using 40% enriched uranium driving one or two 35 MW steam turbines and delivering about 12 MW shaft power. It has 13 fuel assemblies each with 348 fuel rods, and was built indigenously. The reactor went critical in August 2013. A 20 MW prototype unit had operated for several years from 2003. Further vessels in the class are expected to have a 100 MWt PWR reactor.

Brazil's navy was proposing to build an 11 MWt prototype PWR by 2014 to operate for about eight years, with a view to a full-sized PWR version – 2131-R of 48 MWt – using low-enriched uranium being in its 6000 tonne, 100 m long SNBR submarine to be launched by 2025. Apparently none of these plans have proceeded very far. Argentina’s Bariloche Atomic Centre is considering similar plans, for a TR-1700 submarine with nuclear power.

UK nuclear submarine layout

Dismantling decommissioned nuclear-powered submarines has become a major task for US and Russian navies. After defuelling, normal practice is to cut the reactor section from the vessel for disposal in shallow land burial as low-level waste (the rest being recycled normally). In Russia the whole vessels, or the sealed reactor sections, sometimes remain stored afloat indefinitely, though Western-funded programmes are addressing this and all decommissioned submarines were due to be dismantled by 2012. By 2015, 195 out of 201 decommissioned Russian submarines had been dismantled, and the remainder as well as 14 support vessels were to be dismantled by 2020. Decommissioned British submarines are laid up, France has dismantled several of its retired submarines at Cherbourg.

For the USS Enterprise, after defuelling was completed in December 2016, the eight reactor compartments and associated piping were removed and shipped to Hanford for burial with the submarine reactor compartments.

Marine reactors used for power supply, floating nuclear power plants

A marine reactor was used to supply power (1.5 MWe) to a US Antarctic base for ten years to 1972, testing the feasibility of such air-portable units for remote locations.

Between 1967 and 1976 an ex-army US Liberty ship of about 12,000 tonnes built in 1945, the Sturgis (originally Charles H. Cugle) functioned as a floating nuclear power plant (FNPP), designation MH-1A, moored on Gatun Lake, Panama Canal Zone. It had a 45 MWt/10 MWe (net) single-loop PWR which used low-enriched uranium (4-7%). It used 541 kg of U-235 over ten years and provided power to the Canal Zone for nine years at 54% capacity factor. The propulsion unit of the original ship was removed and the entire midsection replaced with a 350 t steel containment vessel and concrete collision barriers, making it about 2.5 m wider than the rest of the ship, now essentially a barge. The containment vessel contained not only the reactor unit itself but the primary and secondary coolant circuits and electrical systems for the reactor.

There are credible anecdotal reports that decommissioned Russian nuclear submarines have been used to provide electricity for remote communities and for oil exploration companies in Siberian Arctic regions, probably in the 1980s.

In the 1970s Westinghouse in alliance with Newport News shipyard developed an Offshore Power Systems (OPS) concept, with series production envisaged at Jacksonville, Florida. In 1972 two 1210 MWe units were ordered by utility PSEG for offshore Atlantic City or Brigantine, New Jersey, but the order was cancelled in 1978. By the time NRC approval was granted in 1982 for building up to eight plants, there were no customers and Westinghouse closed down its OPS division. Westinghouse and Babcock & Wilcox are reported to be revisiting the concept.

Floating power plants are well-established, especially around Africa. Turkish company Karpowership has 25 such vessels supplying over 4000 MWe and with more than 54 GWh delivered. The largest powerships supply 470 MWe.

Russia has built at St Petersburg the first of a series of floating power plants for its northern and far eastern territories. Two OKBM KLT-40S reactors derived from those in icebreakers, but with low-enriched fuel (less than 20% U-235), are mounted on a 21,500 tonne, 144 m long barge. The refuelling interval is 3-4 years onsite, and at the end of a 12-year operating cycle the whole plant is returned to a shipyard for a two-year overhaul and storage of used fuel, before being returned to service. This first unit is designated as a floating power unit (FPU) to take in the cogeneration aspect supplying 210 GJ/h for desalination (40,000 to 240,000 m3/d capacity claimed). See also information paper on Nuclear Power in Russia.

Second-generation Russian FNPPs, known as Optimised Floating Power Units (OFPUs), will have two 175 MWt, 50 MWe RITM-200M reactor units, each with 241 fuel assemblies in a larger reactor vessel. These are lighter but more powerful than the KLT-40S, and thus on a smaller barge – 12,000 tonnes, rather than almost twice that. The mass of both reactor units is 2600 tonnes. Refuelling will be every 12 years over a 60-year service life. They can each supply 730 GJ/h thermal power. Four of these have been ordered to supply 330 MWe to the Baimskaya copper mining project south of Bilibino and Pevek from 2028.

China has two projects for FNPPs. In October 2015 the Nuclear Power Institute of China (NPIC), a China National Nuclear Corporation (CNNC) subsidiary, signed an agreement with UK-based Lloyd's Register to support the development of a floating nuclear power plant using CNNC’s ACP100S reactor, a marine version of the multi-purpose ACP100. Its 310 MWt produces about 100 MWe, and it has 57 fuel assemblies 2.15 m tall and integral steam generators (287°C), so that the whole steam supply system is produced and shipped as a single reactor module. It has passive cooling for decay heat removal. It has been subject to the IAEA Generic Reactor Safety Review process. Following approval by the NDRC as part of the 13th Five-Year Plan for innovative energy technologies, CNNC had planned to start building its ACP100S demonstration floating nuclear plant in 2016, for 2019 operation, but this has been delayed. Lloyd's Register will develop safety guidelines and regulations as well as nuclear standards consistent with offshore and international marine regulations.

China General Nuclear Power Group (CGN) announced in January 2016 that development of its ACPR50S reactor design was approved by the NDRC as part of the 13th Five-Year Plan for innovative energy technologies. Construction of the first demonstration FNPP started in November 2016, with electricity generation expected to begin in 2020. CGN then signed an agreement with China National Offshore Oil Corporation (CNOOC) apparently to provide power for offshore oil and gas exploration and production, and to “push forward the organic integration of the offshore oil industry and the nuclear power industry,” according to CNOOC. The ACPR50S is 200 MWt, 60 MWe with 37 fuel assemblies and two loops feeding four external steam generators. Reactor pressure vessel is 7.4m high and 2.5 m inside diameter, operating at 310°C.

Earlier, SNERDI in Shanghai was designing a CAP-FNPP reactor. This was to be 200 MWt and relatively low-temperature (250°C), so only about 40 MWe with two external steam generators and five-year refuelling. This project has probably given way to the CNNC/NPIC one, though the reactor is similar to CGN’s ACPR50S.

In South Korea, KEPCO Engineering & Construction is developing the BANDI-60S as a 200 MWt/60 MWe two-loop PWR particularly for floating nuclear power plants. In September 2020 KEPCO signed an agreement with Daewoo Shipbuilding & Marine Engineering to develop offshore nuclear power plants. The BANDI-60S is described as ‘block type’ with the external steam generators connected directly nozzle-to-nozzle. Initially the SGs are conventional U-tube, but KEPCO is working on a plate and shell design which will greatly reduce their size. Apart from the SGs, most main components including control rod drives are within the pressure vessel. Primary pumps are canned motor, and decay heat removal is passive. There are 52 conventional fuel assemblies, giving 35 GWd/t burn-up with 48-60 month fuel cycle. Burnable absorbers are used instead of soluble boron. Design operating lifetime is 60 years. The reactor vessel is 11.2 m high and 2.8 m diameter. In October 2023 the American Bureau of Shipping issued an in-principle approval for the nuclear power barge design.

Canadian commercial marine nuclear power developer Prodigy Clean Energy signed an agreement with NuScale Power in May 2021 to support business opportunities for a marine-deployed power station using the NuScale SMR. This followed three years of cooperation on conceptual design and economic assessment for floating nuclear power plants.

Future prospects

With increasing attention being given to greenhouse gas emissions arising from burning fossil fuels for international air and marine transport, particularly dirty bunker fuel for the latter, and the excellent safety record of nuclear-powered ships, it is quite conceivable that renewed attention will be given to marine nuclear powered ships, it is likely that there will be renewed interest in marine nuclear propulsion. The world's merchant shipping is reported to have a total power capacity of 410 GWt, about one-third that of world nuclear power plants.

With a new focus on powering ships with hydrogen or ammonia, nuclear power also has a potential role in providing the hydrogen. See information page on Hydrogen Production and Uses.

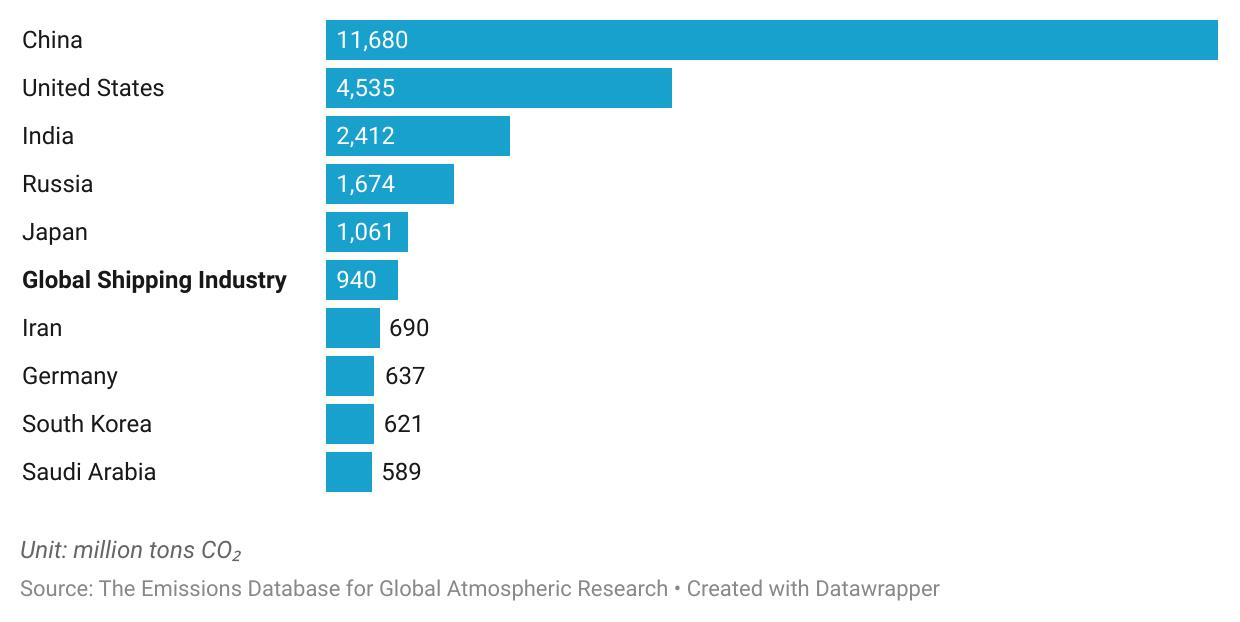

Container ships deliver around 90% of all goods globally. With around 53,000 merchant vessels, the global shipping industry is one of the largest greenhouse gas emitters globally, producing approximately 1 billion tonnes of carbon dioxide (CO2) – while consuming around 6% of the total global oil production annually – accounting for about 3% of all greenhouse gas emissions. As the graph below shows, if the global shipping industry were a country, it would be the sixth largest emitter of CO2 globally.

Annual highest carbon dioxide emissions by country 2020

In 2018 the International Maritime Organization (IMO) adopted the aim of reducing greenhouse gas emissions from shipping by 50% by 2050, compared with 2008. It estimated that shipping accounted for 2.6% of the world CO2 emissions. In 2017 global bunkering totalled 8.9 EJ, with 82% being heavy fuel oil and the balance marine gas oil and diesel. In 2018 the global shipping fleet had a capacity of 2 Gt and it transported 8.9 Gt of freight. Russia’s 61,900 tonne Sevmorput is the only nuclear-powered freighter in service.

The head of the large Chinese shipping company Cosco suggested in December 2009 that container ships should be powered by nuclear reactors in order to reduce greenhouse gas emissions from shipping. He said that Cosco was in talks with China's nuclear authority to develop nuclear powered freight vessels. However, in 2011 Cosco aborted the study after three years, following the Fukushima accident.

In 2010 Babcock International's marine division completed a study on developing a nuclear-powered LNG tanker (which requires considerable auxiliary power as well as propulsion). The study indicated that particular routes and cargoes lent themselves well to the nuclear propulsion option, and that technological advances in reactor design and manufacture had made the option more appealing.

In November 2010 the British maritime classification society Lloyd's Register embarked upon a two-year study with US-based Hyperion Power Generation (now Gen4 Energy), British vessel designer BMT Group, and Greek ship operator Enterprises Shipping and Trading SA "to investigate the practical maritime applications for small modular reactors." The research was to produce a concept tanker-ship design, based on a 70 MWt reactor such as Hyperion's. Hyperion (Gen4 Energy) had a three-year contract with the other parties in the consortium, which planned to have the tanker design certified in as many countries as possible. The project included research on a comprehensive regulatory framework led by the International Maritime Organization (IMO), and supported by the International Atomic Energy Agency (IAEA) and regulators in countries involved.

In response to its members' interest in nuclear propulsion, Lloyd's Register has rewritten its 'rules' for nuclear ships, which concern the integration of a reactor certified by a land-based regulator with the rest of the ship.* The overall rationale of the rulemaking process assumes that in contrast to the current marine industry practice where the designer/builder typically demonstrates compliance with regulatory requirements, in the future the nuclear regulators will wish to ensure that it is the operator of the nuclear plant that demonstrates safety in operation, in addition to the safety through design and construction. Nuclear ships are currently the responsibility of their own countries, but none are involved in international trade. Lloyd's Register said it expected to "see nuclear ships on specific trade routes sooner than many people currently anticipate."

* Chapter VIII of the International Convention for the Safety of Life at Sea (SOLAS), 1974 gives basic requirements for nuclear-powered ships. In 1981 the IMO adopted the Code of Safety for Nuclear Merchant Ships, Resolution A.491(XII), which is still extant and could be updated.

In 2014 two papers on commercial nuclear marine propulsion were published* arising from this international industry project led by Lloyd's Register. They review past and recent work in the area of marine nuclear propulsion and describe a preliminary concept design study for a 155,000 dwt Suezmax tanker that is based on a conventional hull form with alternative arrangements for accommodating a 70 MWt nuclear propulsion plant delivering up to 23.5 MW shaft power at maximum continuous rating (average: 9.75 MW). The Gen4Energy power module is considered. This is a small fast neutron reactor using lead-bismuth eutectic cooling and able to operate for ten full-power years before refuelling, and in service last for a 25-year operational life of the vessel. They conclude that the concept is feasible, but further maturity of nuclear technology and the development and harmonisation of the regulatory framework would be necessary before the concept would be viable.

* Hirdaris et al, 2014.

In 2021 it was suggested that modular molten salt reactors of about 100 MWt would be particularly suitable for marine propulsion due to ambient operating pressure and low-enriched fuel. Shipping company X-Press Feeders has invested in UK-based Core Power, which is promoting modular molten salt reactors for marine propulsion. Since 2020 Core Power has been involved with Southern Company and Terrapower in the USA developing the molten chloride fast reactor as a marine MSR which would never require refuelling during its operational life.

In June 2021 Samsung Heavy Industries (SHI) announced that it would partner with Korea Atomic Energy Research Institute (KAERI) to develop compact molten salt reactors to power ships as well as market offshore power plants. In January 2023 SHI completed a conceptual design for the CMSR Power Barge – a floating nuclear power plant based on compact molten salt reactors. The design of between 200 MWe and 800 MWe, developed by Danish company Seaborg Technologies, would have an operational lifetime of 24 years. SHI plans to commercialize the CMSR Power Barge by 2028.

Apart from naval use, where frequency of refuelling is a major consideration, nuclear power seems most immediately promising for the following:

- Large bulk carriers that go back and forth constantly on few routes between dedicated ports – e.g. China to South America and NW Australia. They could be powered by a reactor delivering 100 MW thrust.

- Cruise liners, which have demand curves like a small town. A 70 MWe unit could give base-load and charge batteries, with a smaller diesel unit supplying the peaks. (The largest afloat today – Oasis class, with 100,000 t displacement – has about 60 MW shaft power derived from almost 100 MW total power plant.)

- Nuclear tugs, to take conventional ships across oceans.

- Some kinds of bulk shipping, where speed may be essential.

In mid-2021 the World Nuclear Transport Institute (WNTI) announced the launch of the Maritime Applications & Nuclear Propulsion Working Group, to discuss and develop rules frameworks for the deployment of next-generation reactors at sea. This is to include nuclear propulsion, floating nuclear power plants, offshore small modular reactors used for hydrogen production and maritime transport of SMRs.

There is a school of thought which says that using nuclear reactors to power ships raises too many questions around port access and security, so the main role of nuclear power for shipping is to make hydrogen and ammonia as carbon-free fuels. One estimate is that producing enough ammonia to fuel the world’s container ships and bulk carriers would require 2300 TWh/yr, nearly as much as total nuclear generation today and more than total wind generation.

The OECD International Energy Agency's Energy Technology Perspectives 2020 in its Sustainable Development Scenario projects about 12% of marine transport being fuelled by hydrogen and 55% by ammonia by 2070, mostly in internal combustion engines rather than fuel cells, with these fuels increasing slowly from 2030 and more rapidly from 2050. Fuel cells with hydrogen are likely to be confined to short-range shipping due to storage costs.

In October 2020 Canadian Nuclear Laboratories was awarded a contract by Transport Canada to develop its Marine-Zero Fuel (MaZeF) assessment tool to analyse the energy ecosystem of marine transport. This to reduce greenhouse gas emissions in line with the IMO 2018 target (i.e. a 50% reduction by 2050, compared with 2008). It will include different technologies that can be used for the production, storage and handling of hydrogen for marine vessels.

Notes & references

General sources

Jane's Fighting Ships, 1999-2000 edition

J Simpson 1995, Nuclear Power from Underseas to Outer Space, American Nuclear Society

The Safety of Nuclear Powered Ships, 1992 Report of NZ Special Committee on Nuclear Propulsion

Rawool-Sullivan et al 2002, Technical and proliferation-related aspects of the dismantlement of Russian Alfa-class submarines, Nonproliferation Review, Spring 2002

Honerlah, H.B. & Hearty, B.P., 2002, Characterisation of the nuclear barge Sturgis, WM’02 conf, Tucson

C. Thompson, Recovering the Kursk, Nuclear Engineering International (December 2003)

Mitenkov F.M. et al 2003, Prospects for using nuclear power systems in commercial ships in Northern Russia, Atomic Energy 94, 4

Hirdaris S.E et al, 2014, Considerations on the potential use of Nuclear Small Modular Reactor (SMR) technology for merchant marine propulsion, Ocean Engineering 79, 101-130

Hirdaris S.E et al, 2014, Concept design for a Suezmax tanker powered by a 70 MW small modular reactor, Trans RINA 156, A1, Intl J Maritime Eng, Jan-Mar 2014

Naval Nuclear Propulsion Program, Office of Naval Reactors, Occupational Radiation Exposure From Naval Reactors’ Department of Energy Facilities, Report NT-14-3, May 2014

Rosatom 2013 Annual Report

US Navy propulsion systems

Ford class aircraft carriers

Naval Aviation Enterprise Air Plan Newsletter 33, Nov 2013

Ole Reistad & Povl Ølgaard, Russian Nuclear Power Plants for Marine Applications, NKS (Nordic Nuclear Safety Research), April 2006

Vladimir Artisiuk, Rosatom Technical Academy (Rosatom Tech), SMR Technology Development in Russia and Capacity Building Supports for Embarking Countries, presented at the IAEA Technical Meeting on Technology Assessment of Small Modular Reactors for Near Term Deployment held on 2-5 October 2017 in Tunis, Tunisia

Viktor Merkulov, Analysis of advanced nuclear technologies applicable in the Russian Arctic, IOP Conference Series: Earth and Environmental Science, Volume 180, conference 1, 012020 (August 2018)

Joint Stock Company 'Afrikantov OKB Mechanical Engineering', RITM brochure (2018)

Peter Lobner, 60 Years of Marine Nuclear Power: 1955-2015, Part 4: Other Nuclear Marine Nations (August 2015)

Peter Lobner, Marine Nuclear Power: 1939-2018, Part 2A, United States - Submarines (July 2018)

Jeremy Gordon, Propelling Decarbonisation, Nuclear Engineering International (February 2021)

Modular Molten Salt Nuclear Power for Maritime Propulsion, The Maritime Executive (14 May 2021)

Magdi Ragheb, Nuclear Naval Propulsion (September 2011)

Thomas Nilsen, Nuclear Reactors in Arctic Russia, The Barents Observer (June 2019)

Navy Virginia (SSN-774) Class Attack Submarine Procurement: Background and Issues, Congressional Research Service (19 October 2021)